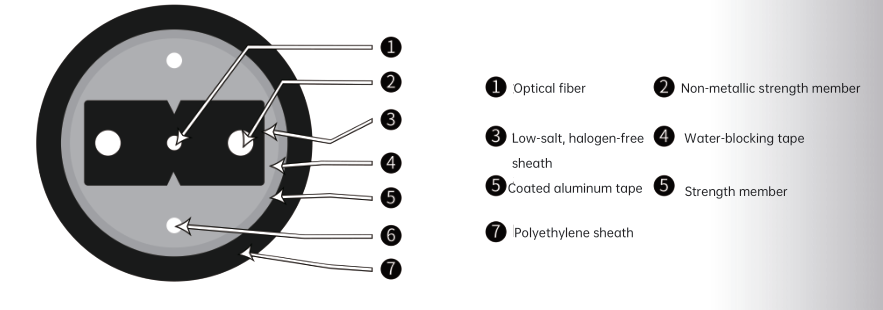

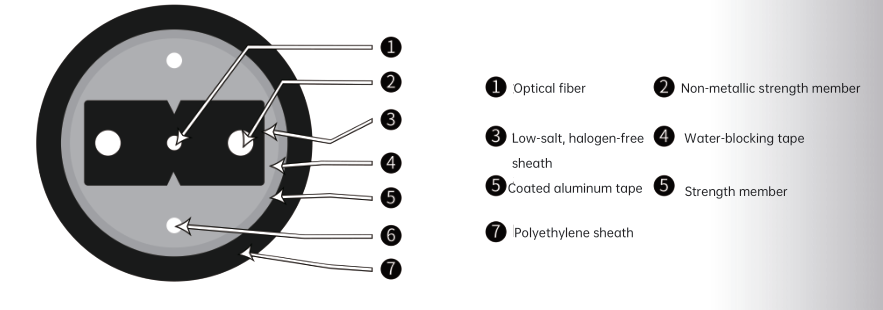

GJYXFHA is a type of communication duct (indoor and outdoor) optical cable with non-metallic strength members and an aluminum-polyethylene sheath

Product Description

For conduit entry of optical cables, the butterfly introduction places the communication unit at the center, with two parallel non-metallic strength members (FRP) placed on both sides. An additional steel wire strength member is attached to the outer side, and then it is extruded with black low smoke zero halogen sheath. It is wrapped with an aluminum foil moisture-proof layer, and finally extruded with PE sheath to form the cable.

Product Feature

◆ Specialized bend-resistant optical fibers provide greater bandwidth and enhance network transmission characteristics.

◆ Single steel wire strength member provides excellent tensile performance to the optical cable.

◆ Two parallel FRP (Fiber Reinforced Plastic) strengthen the cable's compression resistance and protect the optical fibers.

◆ The cable has a simple structure, lightweight, and practical.

◆ Easy stripping facilitates splicing, simplifying installation and maintenance.

◆Low smoke zero halogen flame-retardant sheath is environmentally friendly.

◆ PE outer sheath has excellent UV resistance.

◆ Coated aluminum tape provides moisture-proof layer.

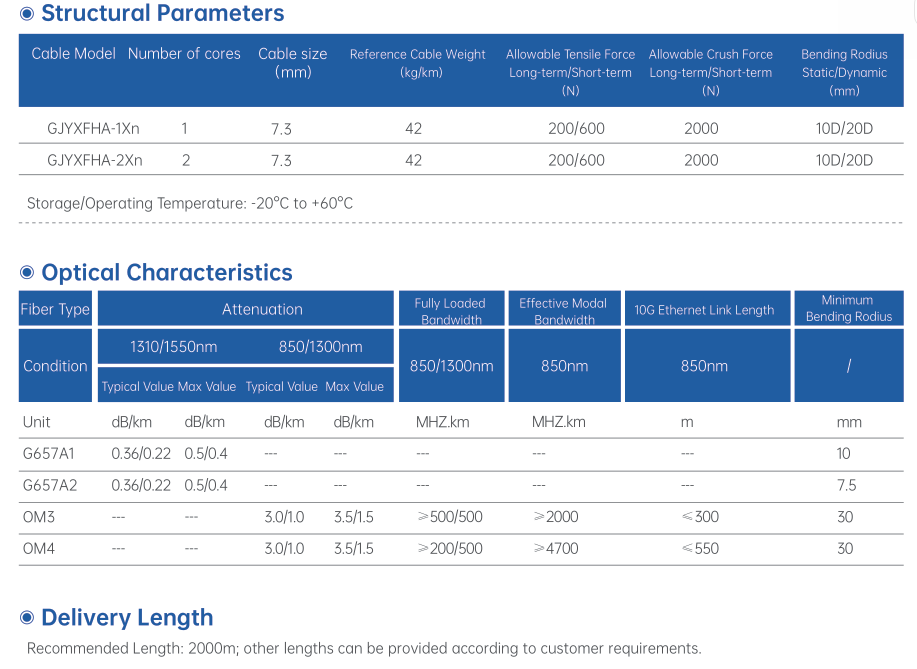

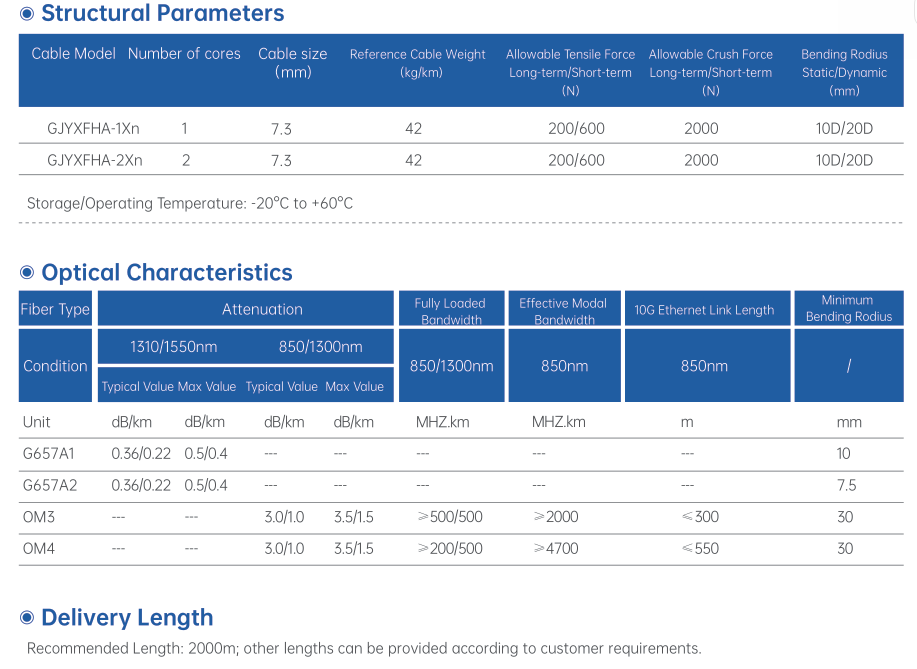

Structural Parameters

Fiber Count: Typically, the number of optical fibers in the cable ranges from 1 to 4 cores, mainly single-core, with other specifications such as dual-core also available, which can meet the communication capacity needs of different users. For example, in fiber-to-the-home (FTTH) access for some household users, a single-core fiber may be sufficient to meet daily services like internet access and TV viewing; while for small enterprises or office scenarios with higher network bandwidth requirements, dual-core or multi-core fibers may be used to achieve higher data transmission rates and redundant backups.

Strength Members: Two parallel non-metallic strength members (FRP) are placed on both sides. These FRP strength members have good compressive performance, which can effectively protect the optical fibers and prevent them from being damaged when subjected to external pressure. Meanwhile, the non-metallic material also enables the optical cable to have better insulation performance and anti-electromagnetic interference capability, making it suitable for various complex electromagnetic environments.

Sheath Structure: The optical cable is first extruded with a black low-smoke zero-halogen sheath. This sheath material has environmental protection characteristics, as it does not produce a large amount of smoke and toxic gases when burned, being relatively friendly to the environment and human health. It is wrapped with an aluminum tape moisture-proof layer, which can effectively block external moisture from entering the interior of the cable and protect the stable optical performance of the optical fibers. Finally, a PE sheath is extruded to form the cable. The PE outer sheath has excellent UV resistance, which can resist outdoor UV radiation, extend the service life of the optical cable, and make it suitable for various indoor and outdoor environments.

Cable Dimensions: Taking the common GJYXFHA-1Xn and GJYXFHA-2Xn as examples, their cable diameters are both 7.3mm. This compact size design makes the cable more convenient for duct laying or indoor wiring, and can adapt to small duct spaces or wall trunking and other laying environments.

Mechanical Performance Parameters

Allowable Tensile Force: The long-term allowable tensile force of GJYXFHA optical cable is 200N, and the short-term allowable tensile force is 600N. This means that during normal use, the cable can withstand a certain amount of tensile force without affecting its performance, but during construction, the short-term applied tensile force should not exceed 600N to ensure that the internal optical fibers and other structures of the cable are not damaged. For example, when performing duct cable pulling construction, attention should be paid to the magnitude of the traction force to avoid exceeding the bearing range of the cable.

Allowable Crush Force: The long-term allowable crush force of this cable is 2000N/100mm, and the short-term allowable crush force is also 2000N/100mm. This indicates that the cable can maintain the integrity of its structure and the stability of its performance when subjected to external pressure. For example, when the cable is squeezed by other surrounding cables or objects in the duct, or when it is subjected to ground pressure outdoors, its crush force parameters can ensure the normal operation of the cable.

Bending Radius: The dynamic bending radius of GJYXFHA optical cable is 10D (where D is the cable diameter), and the static bending radius is 20D. That is to say, during the cable laying process (dynamic situation), the bending radius should not be less than 73mm (7.3mm × 10); after the cable is fixed (static situation), the bending radius should not be less than 146mm (7.3mm × 20). If the bending radius is too small, it will lead to an increase in the attenuation of the optical fiber, and may even cause fiber breakage, affecting communication quality.

Optical Performance Parameters

Fiber Type: Various fiber types can be used, such as 62.5μm (850/1300nm), 50μm (850/1300nm), G.652D (1310/1550nm), G.657A (B) (1310/1550nm), etc. Different fiber types have different optical properties and application scenarios. For example, G.652D fiber is a commonly used single-mode fiber with low attenuation at 1310nm and 1550nm wavelengths, suitable for long-distance, large-capacity communication transmission; while G.657A (B) fiber has better bending performance, making it more suitable for use in environments with small bending radii, such as indoor wiring.

Attenuation Value: For different types of fibers, their attenuation values vary. Taking G.652D fiber as an example, the typical attenuation value at 1310nm wavelength is 0.36dB/km, and the typical attenuation value at 1550nm wavelength is 0.22dB/km. The attenuation value is one of the important indicators to measure the transmission performance of optical fibers. The lower the attenuation value, the longer the distance the signal can transmit in the optical fiber, and the better the signal quality.

Bandwidth: If 50μm (850/1300nm) fiber is used, its minimum LED bandwidth is 400/800MHz·km. Bandwidth determines the frequency range and data rate that the optical fiber can transmit. A higher bandwidth can meet the needs of high-speed data transmission, such as high-definition video transmission, large data download and other services.

Environmental Performance Parameters

Temperature Range: The storage and operating temperature range of GJYXFHA optical cable is -20℃ to +60℃. This means that the cable can work and be stored normally in a relatively wide temperature environment. In winter in cold northern regions, the outdoor temperature may be lower than -20℃. At this time, the cable needs to have good low-temperature performance to ensure that the optical properties and structure of the optical fiber are not affected; in hot summer, the outdoor temperature may exceed +60℃, and the cable also needs to be able to withstand high-temperature environments and maintain stable performance.

Moisture Resistance: Due to the cable having a plastic-coated aluminum tape (APL) moisture-proof layer, it can effectively prevent moisture from invading the interior of the cable. The intrusion of moisture will lead to an increase in the attenuation of the optical fiber, and may even cause corrosion of the optical fiber, affecting the service life of the cable. Therefore, good moisture resistance is very important for the cable to be used in humid environments or underground ducts where water is prone to accumulate.

Flame Retardant Performance: The low-smoke zero-halogen flame-retardant sheath of the cable has good flame retardant performance, which can prevent the spread of fire in case of fire and reduce the damage of fire to the communication system. At the same time, the low-smoke and zero-halogen characteristics also mean that in the event of a fire, a large amount of smoke and toxic gases will not be generated, which is conducive to the evacuation of personnel and the conduct of fire-fighting work.

Other Parameters

Recommended Length: The general recommended length is 2000m, but other lengths can also be provided according to customer requirements. This allows the cable to be customized according to different engineering needs, meeting the length requirements of various actual laying scenarios. For example, in some short-distance indoor wiring projects, only a few hundred meters of cable may be needed; while in some long-distance outdoor duct laying projects, several kilometers of cable may be required.

Note:

This document is for reference only and cannot be used as an attachment to the contract.

For detailed product information, please contact our sales staff.