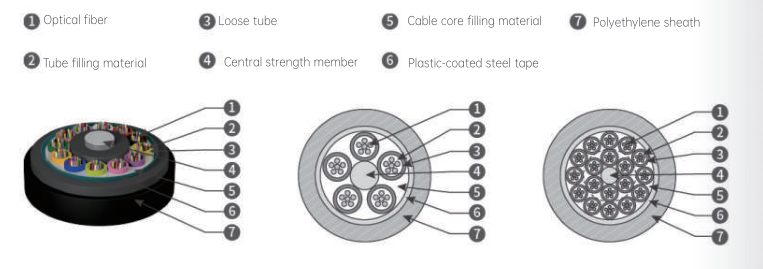

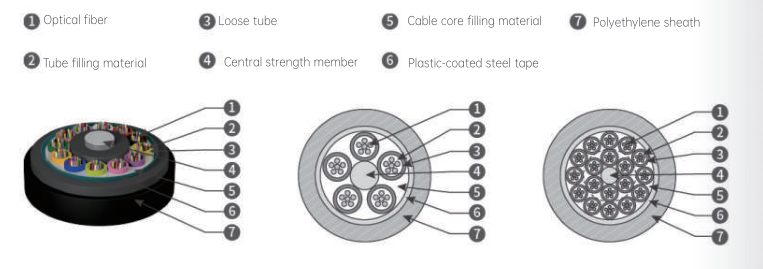

Colored optical fibers are placed into a loose tube made of high modulus material, which is then filled with thixotropic water-blocking gel. The center of the cable core contains a metal strength member. The loose tube(and filling rope)is twisted around the central strength member to form a circular cable core, with gaps in the cable core and between the cable core and steel strip filled with water-blocking gel. After being longitudinally wrapped with plastic-coated aluminum tape and then extruded with a polyethylene inner sheath, the cable is longitudinally wrapped with plastic-coated steel tape and then extruded with a polyethylene outer sheath. Finally, after being armored with a single round steel wire, the cable is extruded with a polyethylene outer sheath.

Product Description

Colored optical fibers are placed into a loose tube made of high modulus material, which is then filled with thixotropic water-blocking gel. The center of the cable core contains a metal strength member. The loose tube(and filling rope)is twisted around the central strength member to form a circular cable core, with gaps in the cable core and between the cable core and steel strip filled with water-blocking gel. After being longitudinally wrapped with plastic-coated aluminum tape and then extruded with a polyethylene inner sheath, the cable is longitudinally wrapped with plastic-coated steel tape and then extruded with a polyethylene outer sheath. Finally, after being armored with a single round steel wire, the cable is extruded with a polyethylene outer sheath.

Product Features

The material of the loose tube itself has good resistance to hydrolysis and high strength. The single round steel wire armor enhances the cable's tensile strength.

◆Filled with thixotropic gel inside the tube, providing crucial sealing protection to the optical fibers.

◆PE sheath has excellent resistance to ultraviolet radiation.

◆A single steel wire central strength member contributes to the parallelism and tensile strength of the optical cable.

◆Possesses good mechanical performance and temperature characteristics. Coated aluminum tape moisture-proof layer.

◆Double-sided Corrugated Steel Tape(PSP)enhances the cable 's resistance to moisture penetration, while the corrugated part can better bond with PE, making the structure more robust. High-quality water-blocking materials prevent longitudinal water ingress into the optical cable.

Optical Characteristics

| Fiber Type | Attenuation(+20℃) | Bandwidth | Numerical

Aperture | Cable Cut-off |

| @850mm | @1300mm | @1310mm | @1550mm | @850mm | @1300mm | Wavelength |

| G.652 |

|

| ≤0.36db/km | ≤0.22db/km | - | - |

| ≤1260nm |

| G.655 |

|

| ≤0.40db/km | ≤0.23db/km | - | - | - | ≤1450nm |

| 50/125μm | ≤3.0db/km | ≤1.0db/km | - | - | ≥500MHz ·km | ≥500MHz ·km | 0.200±0.015NA | - |

| 62.5/125μm | ≤3.3db/km | ≤1.0db/km | - | - | ≥200MHz ·km | ≥500MHz ·km | 0.275±0.015NS | - |

Structural Parameters

Cable Model

(increments by

2 fibers) | Number of

Fibers | Number of Loose Tubes | Number of Filling Ropes | Reference Cable Weight

(kg/km) | Allowable Tensile Force Long-term/Short-term

(N) | Allowable Crush Force Long-term/Short-term

(N) | Bending Radius Static/Dynamic(mm) |

| GYTA53-2~6Xn | 2~6 | 1 | 5 | 177 | 600/1500 | 300/1000 | 10D/20D |

| GYTA53-8~12Xn | 8~12 | 2 | 4 | 177 |

| GYTA53-14~18Xn | 14~18 | 3 | 3 | 177 |

| GYTA53-20~24Xn | 20~24 | 4 | 2 | 177 |

| GYTA53-26~30Xn | 26-30 | 5 | 1 | 177 |

| GYTA53-32~36Xn | 32~36 | 6 | 0 | 177 |

| GYTA53-38~48Xn | 38~48 | 4 | 1 | 194 |

| GYTA53-50~60Xn | 50~60 | 5 | 0 | 194 |

| GYTA53-62~72Xn | 62~72 | 6 | 0 | 204 |

| GYTA53-74~84Xn | 74~84 | 7 | 1 | 239 |

| GYTA53-86~96Xn | 86~96 | 8 | 0 | 239 |

| GYTA53-98~108Xn | 98~108 | 9 | 1 | 275 |

| GYTA53-110~120Xn | 110~120 | 10 | 0 | 275 |

| GYTA53-122~132Xn | 122~132 | 11 | 1 | 312 |

| GYTA53-134~144Xn | 134~143 | 12 | 0 | 312 |

| GYTA53-146~216Xn | 146~216 | 13-18 | 5-0 | 312 |

| Storage and Operating Temperature:-40℃ to+70℃. |

In the construction of modern communication networks, optical cables, as key carriers of information transmission, their performance directly affects the quality and stability of communication. GYTA53 optical cable, as a widely used type in outdoor communication fields, plays an important role in long-distance communication, inter-office communication, and communication scenarios in various complex environments due to its unique parameter characteristics. A deep understanding of the parameter characteristics of GYTA53 optical cable is crucial for the rational selection, correct laying, and efficient maintenance of communication lines.

GYTA53 optical cable can accommodate single-mode or multi-mode fibers, with common fiber core counts ranging from 2 to 300 cores. Single-mode fibers (such as G.652, G.655, etc.) are suitable for long-distance, high-rate data transmission. Their core diameter is small, usually around 9μm, which can effectively reduce dispersion and achieve low-loss transmission of optical signals over long distances. Multi-mode fibers (such as 50/125μm, 62.5/125μm) are often used in short-distance communication and local area networks. Their core diameter is relatively large, allowing multiple modes of optical signals to be transmitted simultaneously, but the transmission distance and rate are limited compared to single-mode fibers. The configuration of different core counts meets the diverse communication needs from small communication branches to large communication trunks.

Fibers are enclosed in loose tubes made of high-modulus plastic. This material has good hydrolysis resistance and high strength, providing reliable physical protection for the internal fibers. The loose tubes are filled with special waterproof ointment, which can isolate moisture, prevent water vapor from damaging the fibers, and buffer external mechanical stress to a certain extent. Generally, the outer diameter of loose tubes is about 1.9 - 2.05mm. The number of loose tubes contained in optical cables with different core counts and the number of fiber cores in each tube vary. For example, some low-core-count optical cables may have only 1 - 2 loose tubes, each containing several cores of fibers; while high-core-count optical cables may include 6 - 12 loose tubes, with a corresponding increase in the number of fiber cores in each tube.

A metal strength member is placed at the center of the cable core, usually made of phosphated steel wire. Phosphated steel wire has high modulus and corrosion resistance, which can significantly enhance the tensile strength of the optical cable. In some optical cables with specific core counts, to further improve the protection effect, the metal strength member is also covered with a layer of polyethylene (PE). The diameter of the strength member is generally about 0.8 - 1.2mm, and the specific value will be adjusted according to the specifications and design requirements of the optical cable. It bears the main tensile force during the laying of the optical cable, ensuring that the fibers inside the optical cable will not be damaged due to excessive tension in various complex construction environments and long-term use.

Loose tubes and filling ropes are stranded around the central strength member into a compact and round cable core structure through "SZ" bidirectional stranding technology. This stranding method not only improves the flexibility of the optical cable, facilitating laying operations, but also enables each loose tube to be evenly distributed in the cable core, effectively dispersing external forces. The gaps in the cable core are filled with water-blocking compounds to achieve full-section water blocking, which can prevent moisture from penetrating along the longitudinal or transverse direction of the optical cable and causing harm to the fibers. The filling rope is usually made of a polymer material with certain elasticity and strength, which plays a filling and supporting role in the cable core, further enhancing the stability of the cable core structure.

Inner Sheath: A plastic-coated aluminum tape (APL) is longitudinally wrapped around the cable core to form a moisture-proof and electromagnetic shielding layer. The aluminum-plastic composite tape has good moisture resistance, which can effectively prevent external moisture from entering the interior of the optical cable. Outside the APL layer, a polyethylene inner sheath is extruded. Polyethylene material has good insulation performance and chemical corrosion resistance, providing further protection for the inner structure. The thickness of the inner sheath is generally about 1.0 - 1.2mm, which tightly wraps the cable core and works together with the APL layer to provide reliable inner protection for the optical cable.

Armoring Layer: A double-sided plastic-coated steel tape (PSP) is longitudinally wrapped around the inner sheath to form an armoring layer. The PSP tape has high strength and good flexibility after special treatment. The armoring layer can greatly enhance the compression and tensile resistance of the optical cable, effectively resisting external mechanical pressure and impact. For example, during direct burial laying, it can withstand the pressure of the soil and possible excavation damage. At the same time, it can also prevent gnawing damage to the optical cable by rodents. The thickness of the steel tape in the armoring layer is usually about 0.15 - 0.2mm, and its longitudinal wrapping method and overlapping width are carefully designed to ensure sufficient protection without affecting the flexibility of the optical cable.

Outer Sheath: Finally, a polyethylene outer sheath is extruded outside the armoring layer. The outer sheath has good ultraviolet resistance and environmental stress cracking resistance, and can adapt to harsh outdoor climate conditions such as sunlight exposure and wind and rain erosion. Its thickness is generally about 1.7 - 1.8mm, providing comprehensive protection for the outer structure, preventing the armoring layer from rusting and corrosion, and extending the service life of the optical cable. In addition, the surface of the outer sheath usually has a certain friction coefficient, facilitating traction and fixing during laying.

Rated Tensile Strength (RTS): Although there is no clear and unified fixed standard value, generally speaking, the RTS design of GYTA53 optical cable will vary according to different application scenarios and core counts. For optical cables with fewer cores, used in short-distance or low-load scenarios, their RTS may be relatively low; while for high-core-count optical cables used in long-distance trunks or complex environments, RTS needs to be designed higher to ensure safe and stable operation under various harsh conditions.

Maximum Allowable Tension (MAT): The short-term allowable tension is ≥3000N, and the long-term allowable tension is ≥1000N. In the actual laying process, such as overhead laying, it is necessary to consider the tension generated by factors such as the optical cable's own weight, wind force, and possible construction traction. MAT ensures that under these circumstances, the optical cable can withstand the corresponding tension without permanent deformation or damage, ensuring the normal operation of the internal fibers. For example, when laying overhead across a large span, by reasonably calculating and selecting GYTA53 optical cables with appropriate MAT, it can effectively avoid the optical cable breaking or fiber performance degradation due to excessive tension.

Annual Average Operating Tension (EDS): EDS is an important long-term performance indicator, which determines the stability of the optical cable during long-term use. Although the specific value is not clearly given, the general design requires that under the action of EDS, the fibers inside the optical cable should not produce strain or additional attenuation. This means that under normal operating conditions such as annual average temperature, no wind, and no ice, the tension borne by the optical cable is in a safe and stable range, which can ensure that the fibers are always in the best working state, thereby ensuring the reliability and stability of communication.

The short-term allowable crushing force is ≥3000N/100mm, and the long-term allowable crushing force is ≥1000N/100mm. During direct burial laying, the optical cable will be subjected to vertical pressure from the soil; in pipeline laying, it may be subjected to pressure from pipeline deformation or other surrounding objects. The good compressive performance of GYTA53 optical cable enables it to maintain structural integrity under these conditions, and the internal fibers are not affected. For example, when the soil above the direct-buried optical cable settles or generates large pressure for other reasons, the compressive structure of the optical cable can effectively disperse the pressure, preventing the fibers from being crushed and causing signal transmission interruption.

Static Bending Radius: The static bending radius is 10 times the cable diameter. After the optical cable is installed and in a static state, its bending radius must meet this requirement. For example, in wiring inside buildings or cable layout in communication equipment rooms, the optical cable may need to be bent to a certain extent to adapt to the spatial layout. At this time, ensuring that the static bending radius meets the standard can avoid damage to the internal structure of the fiber due to excessive bending, causing attenuation and distortion of the optical signal.

Dynamic Bending Radius: The dynamic bending radius is 20 times the cable diameter. During the laying of the optical cable, such as the deployment of overhead optical cables and the threading of pipeline optical cables, the optical cable is in a dynamic moving state and requires a larger bending radius to ensure safety. For example, when using tension pay-off equipment to deploy overhead optical cables, the optical cable will bend with the traction process. At this time, the requirement of dynamic bending radius can prevent the optical cable from being damaged due to excessive bending during movement, ensuring the smooth progress of the laying process.

Operating Temperature Range: The operating temperature range is -40℃ to +60℃, and some products can be extended to -40℃ to +70℃. This enables GYTA53 optical cables to adapt to various climate conditions around the world, whether in cold polar regions or hot desert areas. In low-temperature environments, the materials of the optical cable will not become brittle and can still maintain good flexibility and mechanical properties, ensuring that the fibers are not affected by low temperatures; in high-temperature environments, the structure and material properties of the optical cable are stable, and problems such as sheath softening and fiber performance degradation due to excessive temperature will not occur, ensuring normal communication.

Temperature Cycle Test: The temperature cycle test requires cyclic testing at different temperature steps (such as +20℃, -40℃, +70℃, +20℃). Single-sheathed optical cables are kept at each step for 12 hours, and double-sheathed optical cables are kept at each step for 24 hours, with 2 cycles. Through such tests, simulate the temperature changes that the optical cable may experience in actual use, and test the performance stability of the optical cable under repeated temperature fluctuations. After the temperature cycle test, various performance indicators of the optical cable, such as fiber attenuation and mechanical strength, should still meet the standard requirements to ensure reliable operation in the actual complex temperature environment.

A full-section water-blocking structure is adopted. When conducting a water seepage test on the full section of the optical cable, it must meet the requirement of no water seepage for 8 hours under 1m water column and 1m optical cable. From the filling of waterproof ointment in the loose tubes inside the cable core, to the filling of water-blocking compounds in the cable core gaps, and then to the waterproof design of the outer sheath, the entire optical cable structure forms a multi-level water-blocking system. This excellent water-blocking performance can effectively prevent moisture from entering the interior of the optical cable, avoiding fiber hydrolysis due to moisture, resulting in reduced transmission performance. Whether it is directly buried in a humid underground environment or overhead in areas with more rain, the water-blocking performance of GYTA53 optical cable can provide a strong guarantee for its long-term stable operation.

The outer sheath is made of polyethylene material with good UV resistance. In the outdoor environment, the optical cable is exposed to sunlight for a long time, and ultraviolet rays will cause aging of the material, reducing the material's performance. The UV-resistant outer sheath of GYTA53 optical cable can effectively resist the erosion of ultraviolet rays, slow down the material aging rate, and maintain the physical properties and protective functions of the sheath. After long-term UV irradiation, the outer sheath will not show obvious cracking, embrittlement and other phenomena, thus ensuring the overall structural integrity and performance stability of the optical cable and extending the service life of the optical cable.

Under the environmental condition of 70℃ (24h), the optical cable should have no dripping of filling compounds and coating compounds. This test mainly checks the stability of the filling and coating materials inside the optical cable in high-temperature environments. If these materials drip at high temperatures, it may cause damage to the internal structure of the optical cable, affecting the protection effect and transmission performance of the fibers. GYTA53 optical cable passes strict drip tests to ensure that internal materials can remain stable at high temperatures and will not have a negative impact on the performance of the optical cable.

G.652 Fiber: At +20℃, the attenuation at 1310nm wavelength is ≤0.36dB/km, and at 1550nm wavelength is ≤0.22dB/km. Lower attenuation means less energy loss of optical signals when transmitted in fibers, enabling long-distance signal transmission. For example, in long-distance communication trunks, GYTA53 optical cables using G.652 fibers can transmit signals hundreds of kilometers or more without frequent signal amplification, greatly reducing communication costs and system complexity.

G.655 Fiber: The attenuation at 1310nm wavelength is ≤0.40dB/km, and at 1550nm wavelength is ≤0.23dB/km. The attenuation performance of G.655 fiber at specific wavelengths also meets the requirements of long-distance, high-rate communication. It has low dispersion and attenuation characteristics near the 1550nm wavelength, which is particularly suitable for high-speed communication systems such as DWDM (Dense Wavelength Division Multiplexing), and can transmit multiple optical signals of different wavelengths on one fiber, greatly improving the transmission capacity of the fiber.

Class A Bandwidth (G.652 Fiber): At 850nm wavelength, it is ≥500MHz·km, and at 1300nm wavelength, it is ≥1000MHz·km. Bandwidth reflects the frequency range of signals that can be transmitted by the fiber. The larger the bandwidth, the higher the data rate that can be transmitted. The bandwidth performance of G.652 fiber at different wavelengths enables it to meet the needs of various communication applications. For example, in local area networks, it can be used for high-speed data transmission, supporting a large number of users to conduct data exchange, video conferences and other services online at the same time.

Class A Bandwidth (G.655 Fiber): At 850nm wavelength, it is ≥200MHz·km, and at 1300nm wavelength, it is ≥600MHz·km. Although the bandwidth of G.655 fiber at certain wavelengths is slightly lower than that of G.652 fiber, its excellent performance near the 1550nm wavelength gives it unique advantages in long-distance, high-rate communication systems. By rationally utilizing its bandwidth characteristics, high-speed and large-capacity data communication can be achieved in long-distance transmission.

G.652 Fiber: The numerical aperture is 0.200±0.015NA. The numerical aperture determines the ability of the fiber to receive optical signals, which affects the efficiency of optical signal coupling into the fiber and the bending loss of the fiber. The numerical aperture design of G.652 fiber enables it to effectively control the transmission mode of optical signals in the fiber while ensuring a certain light receiving capacity, reducing modal dispersion and improving transmission performance.

G.655 Fiber: The numerical aperture is 0.275±0.015NA. The numerical aperture of G.655 fiber is relatively large, which means it has a stronger ability to receive optical signals and can couple optical signals into the fiber more effectively. In some application scenarios with high requirements for optical signal strength, this characteristic of G.655 fiber can play an important role, ensuring the stability and reliability of optical signals during transmission.

G.652 Fiber Optic Cable: The cutoff wavelength is ≤1260nm. The cable cutoff wavelength is an important optical parameter, which determines the minimum wavelength that can be transmitted in a single mode in a specific fiber. When the wavelength of the optical signal is greater than the cutoff wavelength, the fiber can achieve single-mode transmission, avoiding problems such as modal dispersion caused by multi-mode transmission, thereby ensuring high-quality transmission of optical signals. The cutoff wavelength design of G.652 fiber optic cable enables it to stably perform single-mode transmission in common communication wavelength ranges (such as 1310nm and 1550nm).

G.655 Fiber Optic Cable: The cutoff wavelength is ≤1480nm. The cutoff wavelength characteristic of G.655 fiber optic cable enables it to achieve good single-mode transmission performance near wavelengths such as 1550nm. This is crucial for its application in long-distance, high-rate communication systems, ensuring that optical signals maintain low attenuation and dispersion during long-distance transmission, achieving high-speed and stable data transmission.

Insulation Resistance: The insulation resistance of the outer sheath of the optical cable (between the armor layer in the outer sheath and the ground) is not less than 2000MΩ•km (tested with DC 500V) after the optical cable is immersed in water for 24 hours. Good insulation performance can prevent current leakage and avoid damage to the optical cable due to electrical faults. In actual use, especially in humid environments or when laid in parallel with power lines, the guarantee of insulation resistance can ensure the safe operation of the optical cable and prevent external electric fields from interfering with signal transmission inside the optical cable.

Dielectric Strength: Between the armor layer in the outer sheath and the ground, after the optical cable is immersed in water for 24 hours, it is tested to be not less than DC 15kV for 2 minutes. For double-sheathed optical cables, it is required that between the armor in the outer sheath and the metal strength member, it is not less than DC 20kV for 5 seconds, in line with GB/T 1408.1 - 2006. Dielectric strength reflects the ability of the optical cable's insulation material to withstand high voltage. Through strict dielectric strength testing, it is ensured that in high-voltage environments, the insulation structure of the optical cable can effectively isolate high voltage, protect internal fibers and other structures from electrical damage, and ensure the safe and stable operation of the communication system.

Optical Cable Outer Diameter: As the number of cores increases, the outer diameter of the optical cable increases accordingly. Generally, the outer diameter of optical cables with 2 - 30 cores is usually around 12.9mm, while the outer diameter of 300-core optical cables may reach about 218.3mm. The outer diameter of the optical cable will affect its space requirements and construction difficulty during laying. Optical cables with smaller outer diameters have advantages in pipeline laying or environments with limited space, facilitating installation and wiring; while high-core-count, large-diameter optical cables are suitable for trunk lines requiring large-capacity transmission. Although the construction difficulty is relatively large, they can meet the needs of large-scale communication.

Optical Cable Weight: The weight is also related to the number of cores. The weight of optical cables with 2 - 30 cores is about 32kg/km - 60kg/km, while the weight of optical cables with 218 - 300 cores is about 299kg/km. The weight of the optical cable is an important factor to consider during laying, especially in overhead laying. An overly heavy optical cable will increase the load on the pole and tower, requiring evaluation and design of the pole and tower strength. At the same time, during transportation and construction, the weight of the optical cable will also affect the selection of construction equipment and the formulation of construction plans.

The service life of GYTA53 optical cable is usually more than 30 years. This is due to its excellent material properties and structural design, which can maintain stable performance during long-term use, reduce the frequency of optical cable replacement, and lower maintenance costs. The selection of high-quality materials such as phosphated steel wire for the strength member, high-modulus plastic for the loose tubes, and polyethylene with good aging resistance for the sheath, combined with the multi-level protective structure design, enables the optical cable to resist various harsh environmental factors and mechanical stresses, ensuring long-term reliable operation.

Application Range: It is widely used in outdoor communication scenarios such as core networks, metropolitan area networks, and access networks, and is also suitable for long-distance communication and inter-office communication. For example, in the backbone network construction of telecom operators, GYTA53 optical cables can be used to connect communication nodes in different cities; in the metropolitan area network within the city, they can be used to connect various base stations, switching centers, etc.; in the access network, they can be used to introduce communication signals from the trunk line to user terminals.

Laying Methods: Suitable for various laying methods such as overhead, pipeline, buried, and direct burial. Overhead laying can use existing utility poles and other infrastructure, with relatively simple construction; pipeline laying requires laying pipelines first and then threading the optical cable into the pipeline, which can protect the optical cable from direct impact of the external environment and facilitate maintenance and management; buried and direct burial laying methods require directly burying the optical cable underground, and attention should be paid to selecting the appropriate burial depth and location to ensure the safety of the optical cable. The adaptability to multiple laying methods makes GYTA53 optical cable have strong versatility in different engineering projects.

Application: Ducts, Aerial, Direct Burial

Note:

a.The suffix Xn in the model indicates the selected fiber d.The cable should not be stored in open-air environ-

type,see Yangtze Fiber Model Explanation for details. ments for more than 6 months,otherwise the spool may

b.The color arrangement of the loose tube and fibers can be damaged.

be found in the chromatogram.e.This document is for reference only and cannot be

C.The minimum thickness of the polyethylene sheath is used as an attachment to the contract.For detailed

1.5mm.product information,please contact our sales staff.