Product Testing

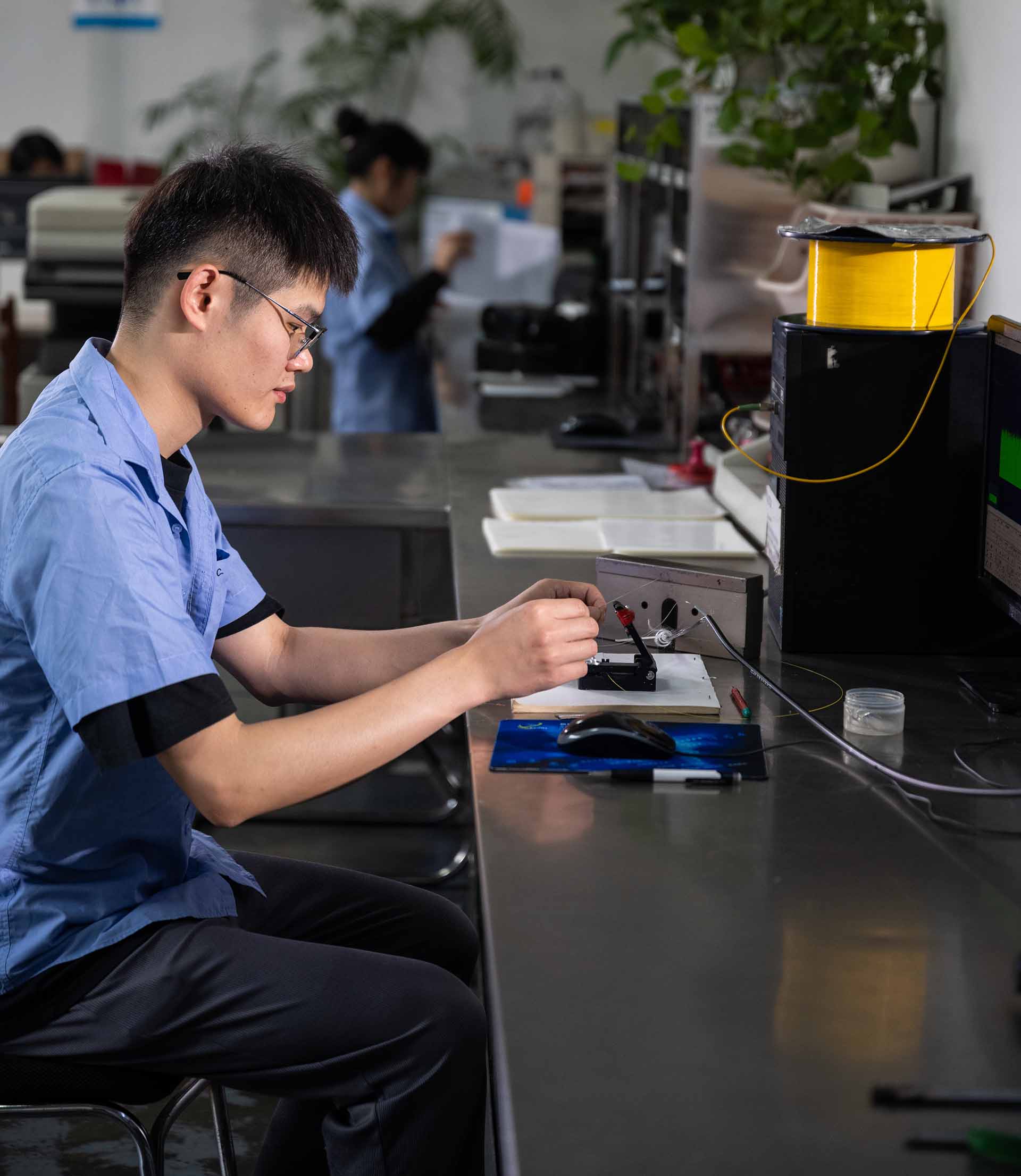

In the laboratory, the employee is dedicated to the fiber optic attenuation test. Dressed in work clothes, he sits upright in front of the operation table, operating the equipment precisely with both hands, and his eyes are fixed on the test instrument. On the table, professional test devices are neatly arranged, and the optical fiber is properly connected.

First, he adjusts the equipment parameters to ensure a stable test environment. Then, he starts the test process, uses a professional instrument to emit a specific optical signal, and after the optical signal is transmitted through the optical fiber, the receiving end accurately captures the change of the optical signal. The instrument displays data in real time. He carefully records and analyzes it, judges the transmission performance of the optical fiber according to the attenuation of optical power, and investigates and troubleshoots attenuation problems caused by materials, bends, etc., providing key data support for fiber optic quality control and subsequent applications. Every step is rigorous and meticulous to safeguard product quality.