GYFTA optical cable is a stranded-layer outdoor communication cable with a non-metallic strength member and aluminum tape longitudinal armor structure. It combines the anti-electromagnetic interference advantages of non-metallic reinforcements with the mechanical protection performance of metal armor, making it widely applicable to various laying scenarios such as pipeline, direct burial, and non-self-supporting overhead installations. It is particularly suitable for complex environments with high mechanical protection requirements.

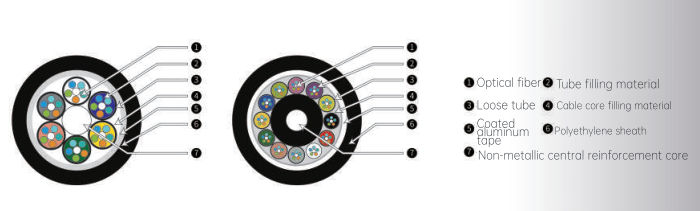

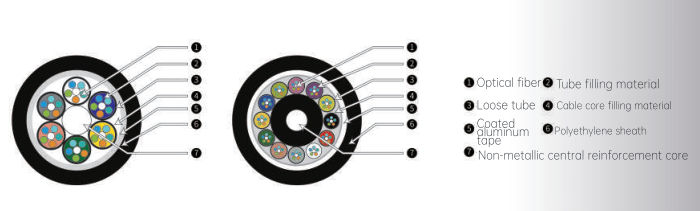

Product Description

Colored optical fibers are placed in a loose tube made of high -modulus material, which is filled with thixotropic gel.

The center of the cable core is a glass fiber reinforced plastic(FRP) . The loose tube(and filler rope)is twisted

around the central reinforcing core to form a circular cable core, which is filled with thixotropic gel in the interstices of the cable core and between the cable core and the aluminum tape. After the aluminum strip is longitudinally

coated, it is extruded with polyethylene sheath to form the cable.

Product Features

The material of the loose tube itself has good resistance to hydrolysis and high strength.

◆Possesses good mechanical performance and temperature characteristics.

◆Filled with thixotropic gel inside the tube, providing crucial sealing protection to the optical fibers.

◆PE sheath has excellent resistance to ultraviolet radiation.

◆Single non-metallic central reinforcing core. Coated aluminum tape moisture-proof layer.

Structural Parameters

GYFTA optical cable uses Glass Fiber Reinforced Plastic (FRP) as the central strength member, and this material selection has multiple advantages. The elastic modulus of FRP material can reach 100-120 GPa, with a tensile strength of ≥1200 MPa. While providing strong structural support, it avoids the problem of induced current generated by metal strength members in strong electromagnetic environments. The diameter of the FRP strength member varies according to the number of cores in the cable, usually ranging from 2.5-4.5 mm. Its surface undergoes special roughening treatment, which can form a good bond with the surrounding stranded structure, effectively dispersing external forces. Compared with traditional metal strength members, FRP material has a density of only 2.0-2.2 g/cm³, reducing the overall weight of the cable by about 30%, which greatly reduces the difficulty of laying and the load on supporting structures.

The loose tube is a key component for protecting optical fibers. GYFTA optical cable uses Polybutylene Terephthalate (PBT) to manufacture loose tubes. PBT material has excellent mechanical properties, with a tensile strength of ≥50 MPa and an elongation at break of ≥200%. Its glass transition temperature is as high as 220°C or more, enabling it to maintain stable performance in the temperature range of -40°C to +70°C. The inner diameter of the loose tube is usually 2.5-3.5 mm, which can accommodate 2-12 optical fibers with a diameter of 250 μm. The tube is filled with special waterproof ointment, which has a dropping point of ≥120°C. It will not flow in high-temperature environments and will not harden and lose its buffering effect in low-temperature environments, effectively buffering the impact of external shocks and vibrations on the optical fibers.

The optical fibers in the loose tube adopt excess length control technology, with the excess length rate precisely controlled between 0.5% and 0.8%. This design is achieved through a sophisticated stranding process, ensuring that the optical fibers will not be excessively stretched or squeezed under temperature changes and mechanical stress, thereby ensuring the stability of optical performance. The color of the loose tubes adopts industry-standard color coding, including blue, orange, green, brown, gray, white, red, black, yellow, purple, pink, turquoise, etc., facilitating core identification during cable splicing.

The cable core of GYFTA optical cable adopts a stranded-layer structure design. Loose tubes and filling ropes are arranged around the central strength member in an SZ stranding manner, with a stranding pitch of 20-30 times the cable diameter. This stranding method makes the cable core structure compact and round, with a diameter deviation controlled within ±0.5 mm, which is beneficial to subsequent armor and sheath processing. The gaps in the cable core are filled with water-blocking yarn and water-blocking paste. The water absorption capacity of the water-blocking yarn is ≥20 times its own weight, which can quickly expand when encountering water to form a water-tight barrier. The longitudinal water-blocking performance reaches the standard of ≤0.1 mL/m, fully meeting the requirements of IEC 60794-1 standard for longitudinal water blocking.

The armor layer is an important feature of GYFTA optical cable, made of high-strength aluminum tape with a thickness of 0.2-0.3 mm through longitudinal wrapping. The aluminum tape is pre-treated with high surface cleanliness, a tensile strength of ≥120 MPa, and an elongation rate of ≥15%, ensuring no cracking during the longitudinal wrapping process. The aluminum tape is longitudinally wrapped in an overlapping manner with an overlap width of ≥6 mm, and is tightly combined with the cable core through a continuous extrusion process to form an effective mechanical protection layer, which can resist external mechanical impacts, lateral pressure, etc. The aluminum tape armor layer not only provides mechanical protection but also plays a certain shielding role, reducing the impact of external electromagnetic interference on optical signal transmission.

The outer sheath of GYFTA optical cable is made of High-Density Polyethylene (HDPE) through extrusion. The thickness of the sheath ranges from 1.5-2.5 mm depending on the cable diameter, with the minimum thickness not less than 85% of the design value. HDPE material has excellent comprehensive performance, with a tensile strength of ≥20 MPa and an elongation at break of ≥300%, which can withstand tensile and bending stresses during laying and use. The sheath material is added with ultraviolet stabilizers and carbon black, with the carbon black content controlled between 2.5%-3.0%, enabling the cable to have good anti-ultraviolet aging performance. After 1000 hours of xenon lamp aging test, the tensile strength retention rate is ≥80% and the elongation at break retention rate is ≥70%.

The surface of the sheath is smooth and flat, without defects such as bubbles, cracks, or depressions, and the printing is clear and durable, including information such as cable model, number of cores, manufacturer's logo, and length marking. The error of the length marking does not exceed ±0.5%. The sheath is tightly combined with the inner armor structure, with a peel strength of ≥1.5 N/mm, ensuring that the sheath and the armor layer do not separate during laying and use.

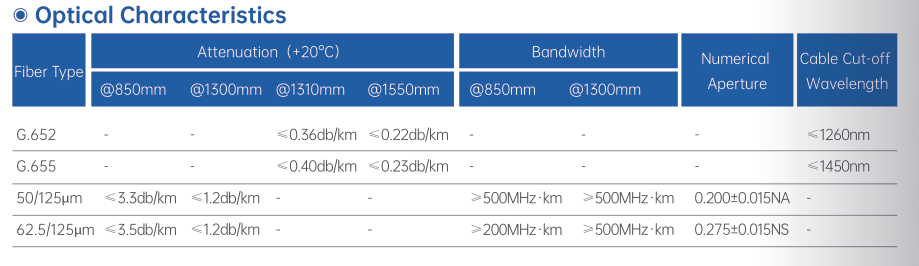

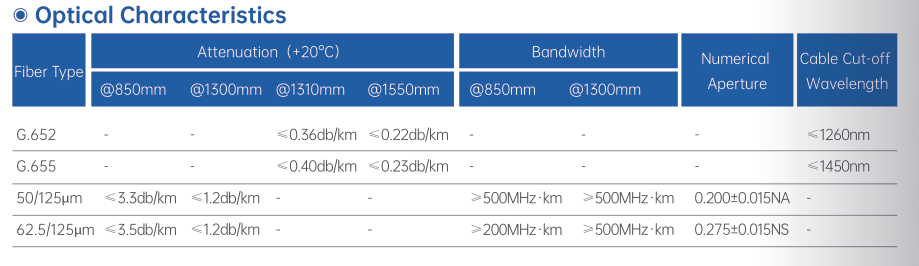

GYFTA optical cable can use single-mode or multi-mode fibers as the transmission medium to meet the needs of different communication scenarios. For single-mode fibers (G.652D), the attenuation coefficient at 1310 nm wavelength is ≤0.36 dB/km, at 1550 nm wavelength is ≤0.22 dB/km, and at 1625 nm wavelength is ≤0.24 dB/km; when using G.655 non-zero dispersion shifted fibers, the attenuation coefficient at 1550 nm wavelength is ≤0.22 dB/km, which can meet the low-loss requirements of long-distance communication.

In terms of multi-mode fibers, the attenuation of 50/125 μm fibers at 850 nm wavelength is ≤3.0 dB/km, and at 1300 nm wavelength is ≤1.0 dB/km; the attenuation of 62.5/125 μm fibers at 850 nm wavelength is ≤3.5 dB/km, and at 1300 nm wavelength is ≤1.5 dB/km. The attenuation unevenness of all fibers is ≤0.1 dB/km, ensuring the stability of signal transmission. In the temperature cycle test (-40°C to +70°C, 5 cycles), the fiber attenuation change is ≤0.05 dB/km, demonstrating its optical performance stability under extreme temperature conditions.

The dispersion performance of single-mode fibers is a key indicator for high-speed communication systems. The dispersion coefficient of G.652D fibers near the zero-dispersion point at 1310 nm wavelength is ≤3.5 ps/(nm·km); at 1550 nm wavelength, the dispersion coefficient is ≤18 ps/(nm·km), which can support 10 Gbps signal transmission over a distance of more than 40 km. The dispersion coefficient of G.655 fibers in the 1530-1565 nm wavelength range is controlled between 2-10 ps/(nm·km), effectively suppressing the four-wave mixing effect, making it suitable for dense wavelength division multiplexing (DWDM) system applications.

The bandwidth performance of multi-mode fibers is also excellent. The effective modal bandwidth of 50/125 μm fibers at 850 nm wavelength is ≥2000 MHz·km, and at 1300 nm wavelength is ≥500 MHz·km; the effective modal bandwidth of 62.5/125 μm fibers at 850 nm wavelength is ≥200 MHz·km, and at 1300 nm wavelength is ≥500 MHz·km, which can meet the transmission needs of scenarios such as high-speed Ethernet and data center interconnection.

The cut-off wavelength of the fiber is crucial for single-mode transmission. The cable cut-off wavelength of G.652D fibers is ≤1260 nm, ensuring single-mode transmission at 1310 nm and above wavelengths. The mode field diameter of the fiber is 9.3±0.5 μm at 1310 nm wavelength and 10.5±0.5 μm at 1550 nm wavelength, which ensures low splicing loss between fibers.

The macro-bending loss of the fiber at 1550 nm wavelength, when wound 10 turns with a 30 mm radius, is ≤0.1 dB; under the same conditions at 1310 nm wavelength, the loss is ≤0.2 dB. The micro-bending loss is verified through temperature cycle and vibration tests. Under various environmental stress conditions, the micro-bending additional loss is ≤0.1 dB/km, ensuring long-term stable transmission of the cable in complex environments.

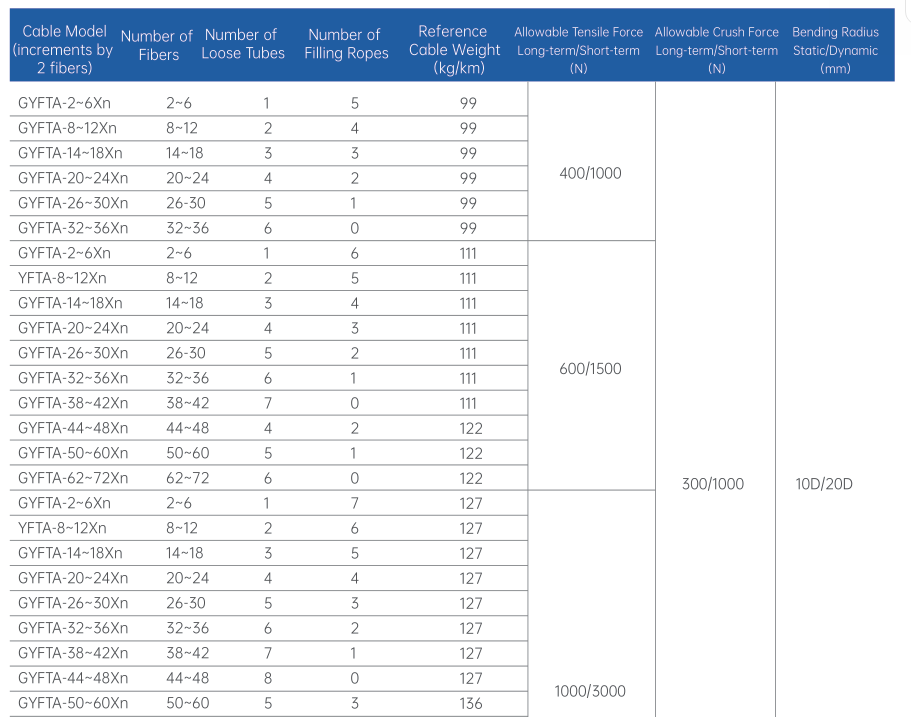

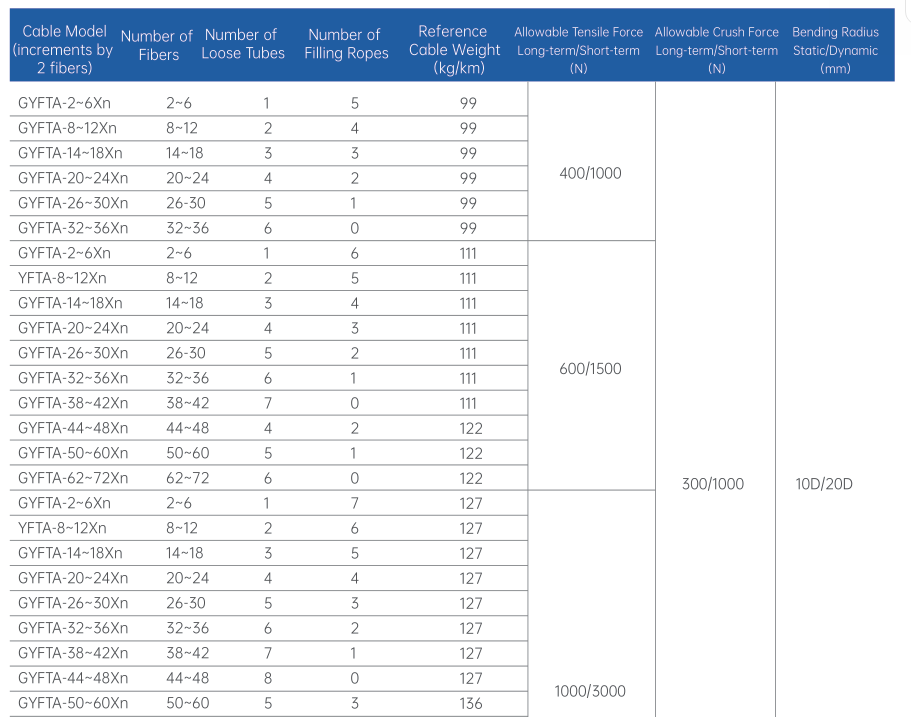

The tensile performance of GYFTA optical cable is guaranteed by a reasonable structural design. Its long-term allowable tensile strength (tensile force sustained during installation and use) is 1000 N for 2-24 core cables, 1500 N for 25-144 core cables, and 2000 N for 145-288 core cables. The short-term allowable tensile strength (tensile force sustained briefly during laying) is 3000 N, 4000 N, and 5000 N respectively, meeting the needs of different laying methods.

In the tensile test, after the cable is subjected to the specified tensile force, the additional attenuation of the fiber is ≤0.1 dB/km, and there is no mechanical damage. After the tensile force is removed, the fiber attenuation should return to the initial value, demonstrating that the cable structure remains stable under tensile force and will not cause permanent damage to the fiber. The synergistic effect of the FRP strength member and the aluminum tape armor layer controls the tensile strain of the cable within 0.2%, which is much lower than the breaking strain of the fiber (≥1.0%).

Optical cables are subject to various lateral pressures during laying and use. The long-term allowable lateral pressure (sustained pressure) of GYFTA optical cable is 300 N/100 mm, and the short-term allowable lateral pressure (briefly sustained pressure during installation) is 1000 N/100 mm. In the compressive test, after the cable is subjected to the specified pressure, the additional attenuation of the fiber is ≤0.1 dB/km, and there is no obvious deformation or damage to the cable structure.

The aluminum tape armor layer plays a key role in compressive performance. It can evenly distribute external pressure to the entire cable core, avoiding excessive local pressure that may damage the fiber. The high-modulus material of the loose tube also has good compressive performance, which can protect the internal fiber from extrusion. Through the armor structure optimized by finite element analysis, when the cable is subjected to lateral pressure, the pressure on the fiber in the loose tube is ≤5 N, which is much lower than the compressive limit of the fiber.

GYFTA optical cable has good flexibility, with a static bending radius (bending radius in a fixed state after installation) of 10 times the cable diameter and a dynamic bending radius (bending radius in a moving state during laying) of 20 times the cable diameter. For a cable with a diameter of 10 mm, the static bending radius is ≥100 mm, and the dynamic bending radius is ≥200 mm.

In the bending test, after the cable is bent with the specified radius, the additional attenuation of the fiber at 1310 nm and 1550 nm wavelengths is ≤0.1 dB/km. After repeated bending tests (bending radius is 20 times the cable diameter, bending times ≥100), there is no obvious change in fiber attenuation, demonstrating that the cable has good bending fatigue resistance. This characteristic makes GYFTA optical cable suitable for scenarios that require bending, such as pipeline corners and wall corner laying.

The impact resistance of the cable is verified through impact tests. The test uses 15 J impact energy, with an impact hammer mass of 1.5 kg, impacting once in each of the four quadrants of the cable circumference. After impact, the cable sheath and armor layer should not have cracks or fractures, and the additional attenuation of the fiber is ≤0.1 dB/km without permanent damage.

The impact energy of GYFTA optical cable is absorbed by the aluminum tape armor layer and the buffer structure. The aluminum tape undergoes plastic deformation when impacted, absorbing most of the impact energy, protecting the internal loose tube and fiber from damage. The waterproof ointment in the loose tube also plays a buffering role, further reducing the impact on the fiber.

GYFTA optical cable has a wide operating temperature range, capable of working normally in an ambient temperature of -40°C to +70°C, and the storage temperature range is -50°C to +80°C. In the high and low-temperature cycle test, after the cable undergoes 5 cycles of -40°C (maintained for 16 hours) to +70°C (maintained for 8 hours), the attenuation change of the fiber is ≤0.05 dB/km, the sheath has no cracking or hardening, and the mechanical performance retention rate is ≥80%.

In low-temperature environments, the HDPE sheath does not become brittle, and its low-temperature impact strength (-40°C) is ≥20 kJ/m²; in high-temperature environments, the thermal deformation temperature of the sheath material is ≥80°C, without softening and deformation. The loose tube material has excellent hydrolysis resistance. After being placed in a high-temperature and high-humidity environment (85°C, 85% relative humidity) for 1000 hours, the tensile strength retention rate is ≥80%, ensuring long-term reliability.

GYFTA optical cable adopts a full-section water-blocking design, with excellent waterproof performance. The longitudinal water-blocking performance passes the 1 m water column pressure test, with no water seepage within 8 hours; the radial water-blocking performance passes the 100 kPa water pressure test, with no water seepage within 24 hours. The water absorption rate of the cable sheath material is extremely low, with a water absorption rate of ≤0.01% when immersed in distilled water at 23°C for 24 hours, which can effectively prevent water penetration.

The synergistic effect of water-blocking yarn and water-blocking paste forms multiple waterproof barriers. The water-blocking yarn swells rapidly when encountering water, filling the cable core gaps and preventing longitudinal spread of water; the water-blocking paste forms a sealing layer in the loose tube and cable core gaps, further blocking the water path. This full water-blocking design makes GYFTA optical cable suitable for scenarios that may come into contact with water, such as humid environments, underground laying, and bridge/culvert crossings.

The weather resistance of the cable includes anti-ultraviolet aging, ozone aging resistance, and chemical corrosion resistance. The ultraviolet stabilizer added to the HDPE sheath enables the cable to be used for a long time in outdoor exposed environments. After 1000 hours of xenon lamp aging test (simulating outdoor sunlight exposure), the tensile strength and elongation at break retention rates of the sheath are both ≥80%, with no aging phenomena such as cracking or discoloration.

In the ozone aging test (ozone concentration 200 pphm, temperature 40°C, relative humidity 60%, test time 168 hours), the cable sheath has no cracks or other damages. The cable has certain resistance to common acid and alkali environments. After being immersed in a solution with pH 4-9 for 30 days, the sheath performance has no obvious changes, making it suitable for use in industrial areas that may have mild chemical pollution.

In the vibration test, the cable is subjected to sinusoidal vibration of 10-500 Hz, with an acceleration of 10 m/s², and vibrated for 2 hours in each axial direction. After vibration, there is no obvious change in fiber attenuation, and the joints are not loose. This performance makes GYFTA optical cable suitable for environments with vibration, such as rail transit and industrial plants.

For areas that may suffer from rodent and ant damage, GYFTA optical cable can use rodent and ant-proof sheath materials, which can effectively prevent gnawing by adding special repellents. The rodent-proof performance passes the GB/T 21529-2008 standard test, with no obvious gnawing damage within 28 days; the ant-proof performance passes similar tests, which can effectively resist damage from termites and other insects.

GYFTA optical cable offers a wide range of core count options, from 2 cores to 288 cores, to meet the needs of different scales of communication networks. 2-12 core cables are mainly used in access networks, user premises networks, and other scenarios; 24-96 core cables are suitable for metropolitan area networks, industrial park interconnections, and other scenarios; 144-288 core cables are used in backbone networks, large data center interconnections, and other scenarios requiring large-capacity transmission.

The diameter and weight of the cable increase with the number of cores. A 2-core cable has a diameter of approximately 6-8 mm and a weight of approximately 80-100 kg/km; a 24-core cable has a diameter of approximately 10-12 mm and a weight of approximately 150-180 kg/km; a 144-core cable has a diameter of approximately 16-18 mm and a weight of approximately 300-350 kg/km; a 288-core cable has a diameter of approximately 20-22 mm and a weight of approximately 450-500 kg/km. The structural design of cables with different core counts ensures good mechanical and optical performance.

The structural design of GYFTA optical cable makes it suitable for various laying methods: when laid in pipelines, the smooth sheath and reasonable diameter of the cable allow it to be laid by air blowing or traction, with an air-blown laying speed of 60-80 m/min and a maximum laying distance of 1000 m; when directly buried, the aluminum tape armor layer can provide certain mechanical protection, and with appropriate burial depth (usually ≥0.8 m), it can resist the impact of general ground activities; when laid in non-self-supporting overhead, the cable can be hung on steel strands through hooks, and its lightweight design reduces the load on the overhead lines.

For special environments, GYFTA optical cable can also be used with auxiliary facilities such as protective tubes and corrugated pipes to further improve the protection level. When laid near railways and highways, it can withstand certain vibration and impact; in high-altitude areas, its wide temperature design can adapt to large temperature differences between day and night; in coastal areas, its salt spray resistance (no obvious corrosion after 500 hours of salt spray test) enables it to resist sea wind erosion.

Metropolitan Area Network Construction: GYFTA optical cable, as the access layer and convergence layer cable of the metropolitan area network, can meet the needs of high-density user access and support the integrated transmission of multiple services.

Industrial Park Communication: In industrial environments, the anti-electromagnetic interference and mechanical protection performance of the cable ensure the stable operation of the communication system, supporting industrial automation, video surveillance, and other services.

Smart Community Wiring: Provides high-speed broadband access for communities, supporting high-definition TV, smart home, and other services, and its full water-blocking design adapts to the underground pipeline environment of the community.

Transportation Hub Communication: In transportation hubs such as railway stations and bus stations, the vibration resistance and impact resistance of the cable ensure smooth communication, supporting key services such as ticketing systems and security monitoring.

Mine Communication: In the ground communication system of mines, the mechanical strength and environmental adaptability of the cable meet the communication needs of the complex mining environment.

The production and manufacturing of GYFTA optical cable strictly follow relevant domestic and foreign standards, including GB/T 7424.1-2010 "General Specification for Optical Fibre Cables", YD/T 901-2018 "Stranded Outdoor Optical Cables for Communication", IEC 60794-1 "Generic Specification for Optical Fibres and Cables", etc. The cable has passed a series of rigorous tests.

Application: Ducts, Aerial

Note:

a.The suffix Xn in the model indicates the selected fibertype, see Yangtze Fiber Model Explanation for details.

b.The color arrangement of the loose tube and fibers can be found in the chromatogram.

c.The minimum thickness of the polyethylene sheath is 1.5mm.

d.The cable should not be stored in open-air environ-ments for more than 6 months, otherwise the spool may

be damaged.

e.This document is for reference only and cannot be used as an attachment to the contract. For detailed product

information, please contact our sales staff.