GYXTA33 optical cable, with its central tube structure and double-layer steel wire armor, performs excellently in mechanical protection, optical performance, and environmental adaptability, especially suitable for complex scenarios such as direct burial, underwater, and railways. Its design balances high strength and lightweight, providing a solid guarantee for the reliability of communication networks. In the future, with the development of 5G, industrial Internet, and other technologies, the application of GYXTA33 in long-distance and high-bandwidth transmission fields will further expand.

Product Description

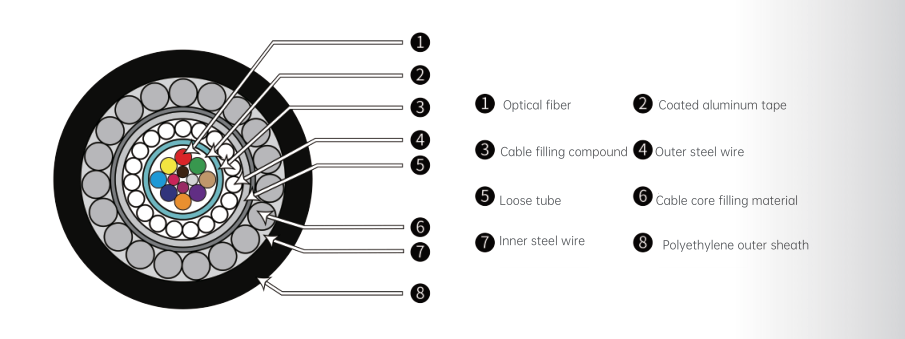

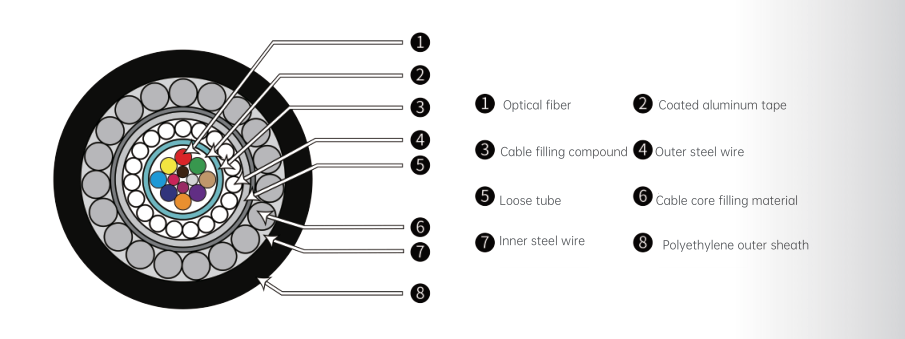

Colored optical fibers are placed into a loose tube made of high-modulus and water-resistant material. The loose tube is filled with thixotropic water-blocking gel. Around the loose tube, there is a layer of fine circular steel wires twisted to form a compact and round cable core. The interstices inside the cable core are filled with water-blocking material. After longitudinal wrapping with coated aluminum tape, it is extruded with a layer

of polyethylene inner sheath, then armored with a single fine circular steel wire, and finally extruded with a polyethylene outer sheath to form the cable.

Product Features

◆Exhibits good mechanical performance and temperature characteristics.

◆Double-layer single fine circular steel wire armor enhances the cable's tensile strength.

◆The material of the loose tube has good hydrolysis resistance and excellent pressure resistance.

◆Filled with special grease inside the tube, providing crucial protection for the optical fibers.

◆Features a moisture-resistant layer of coated aluminum tape.

◆Small size, lightweight, and easy to install.

GYXTA33 uses phosphated steel wire as the central strength member, with a diameter usually of 2.5-4.5mm, a tensile strength of ≥3000N, and excellent corrosion resistance. Compared with the stranded-layer structure, the central tube design makes the cable more compact, with a smaller diameter (e.g., 12-core cable has a diameter of about 10-12mm) and a 15%-20% weight reduction, while still maintaining equivalent mechanical strength.

The central tube is filled with special waterproof ointment with a dropping point of ≥120℃, which remains fluid within the temperature range of -40℃ to +70℃, effectively buffering the impact of external shocks on the optical fibers.

Double-layer fine steel wire armoring

The inner layer of steel wire has a diameter of 0.4-0.6mm, and the outer layer has a diameter of 0.6-0.8mm, with a total armor thickness of ≥1.2mm, providing double mechanical protection.

The surface of the steel wire is galvanized, with no obvious corrosion in the salt spray test (500 hours), showing excellent weather resistance.

The lateral pressure resistance is ≥2000N/100mm (long-term), which can resist external forces such as mechanical rolling and rock extrusion.

Aluminum-polyethylene bonded sheath (APL)

The aluminum tape has a thickness of 0.2-0.3mm, with a longitudinal wrapping overlap width of ≥6mm, tightly bonded to the polyethylene sheath, and excellent radial moisture resistance (no water seepage under 100kPa water pressure for 24 hours).

The outer sheath is made of high-density polyethylene (HDPE), added with 2.5%-3.0% carbon black, and its UV aging resistance passes the 1000-hour xenon lamp test, with a tensile strength retention rate of ≥80%.

Loose tube material: Polybutylene terephthalate (PBT), with a tensile strength of ≥50MPa, a glass transition temperature of 220℃, and excellent hydrolysis resistance (strength retention rate ≥80% after 1000 hours at 85℃/85% humidity).

Optical fiber excess length control: The excess length rate is 0.5%-0.8%, ensuring that the optical fiber is not stretched when the temperature changes through a precision stranding process.

Full-section water blocking: The cable core is filled with water-blocking yarn (water absorption ≥20 times its own weight) and water-blocking ointment, with longitudinal water-blocking performance ≤0.1mL/m, meeting the IEC 60794-1 standard.

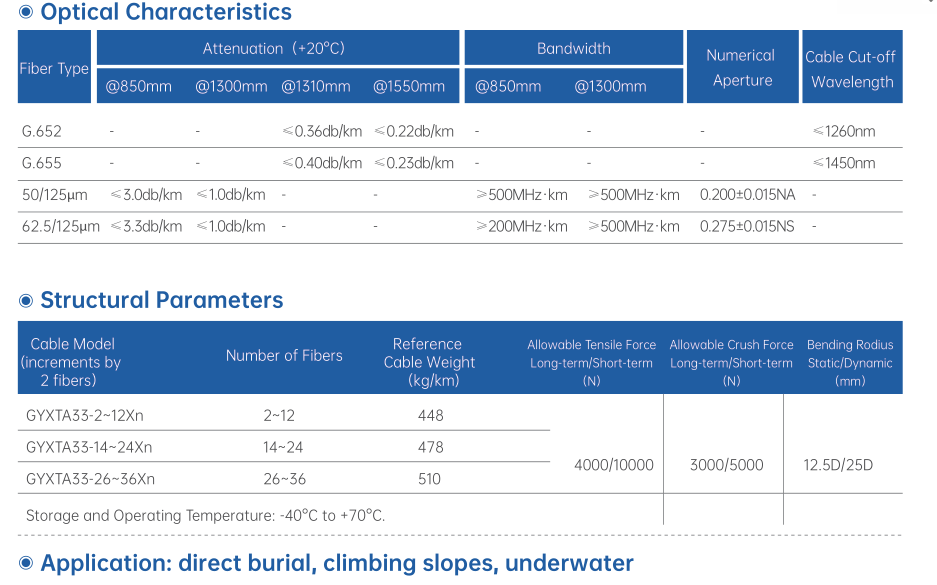

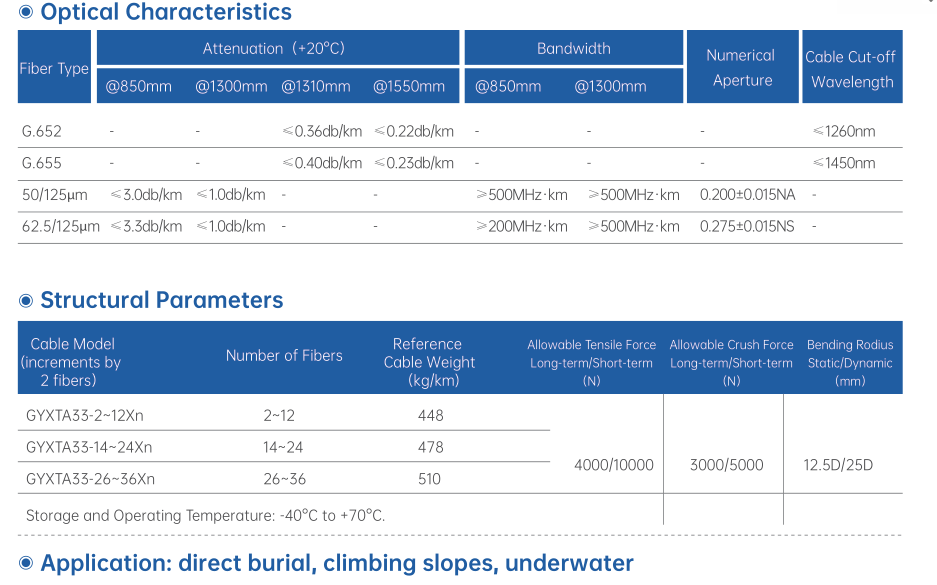

GYXTA33 supports single-mode and multi-mode optical fibers, with typical parameters as follows:

| Fiber type | Wavelength | Attenuation coefficient (dB/km) | Remarks |

|---|

| Single-mode G.652D | 1310nm | ≤0.36 | Supports 10Gbps transmission over 40km+ |

| 1550nm | ≤0.22 | Suitable for DWDM systems |

| Multi-mode 50/125μm | 850nm | ≤3.0 | Effective modal bandwidth ≥2000MHz·km |

| 1300nm | ≤1.0 | Bandwidth ≥500MHz·km |

In the temperature cycle test (-40℃ to +70℃, 5 cycles), the fiber attenuation change is ≤0.05dB/km, demonstrating stability in extreme environments.

Single-mode fiber: G.652D has a dispersion coefficient of ≤18ps/(nm·km) at 1550nm, and G.655 fiber has a dispersion coefficient of 2-10ps/(nm·km) in the 1530-1565nm range, supporting high-speed and long-distance transmission.

Multi-mode fiber: The 50/125μm fiber has an effective modal bandwidth of ≥2000MHz·km at 850nm, meeting the needs of short-distance high-speed interconnection in data centers.

Cut-off wavelength: The cable cut-off wavelength of G.652D is ≤1260nm, ensuring single-mode transmission at 1310nm and above wavelengths.

Macrobending loss: At 1550nm wavelength, the loss of 10 turns wrapped with a 30mm radius is ≤0.1dB, adapting to pipeline bending scenarios.

Long-term allowable tensile force: 1500N for 2-24 core cables, 2000N for 25-144 core cables, and 2500N for 145-288 core cables.

Short-term allowable tensile force: 4000N, 5000N, and 6000N respectively, meeting the requirements of traction laying.

Strain control: Under maximum tension, the fiber strain is ≤0.2%, much lower than the breaking strain (≥1.0%).

Long-term lateral pressure: 300N/100mm, suitable for direct burial scenarios; short-term lateral pressure is 1000N/100mm, which can withstand temporary rolling by construction machinery.

Armor layer protection: The double-layer steel wire armor enables the cable to have no obvious deformation under 1000N/100mm pressure, and the additional attenuation of the fiber is ≤0.1dB/km.

Static bending radius: 10 times the cable diameter (e.g., 100mm for a 10mm cable), dynamic bending radius is 20 times the cable diameter (200mm).

Bending fatigue resistance: After 100 bends with 20 times the cable diameter, there is no obvious change in fiber attenuation.

Operating temperature: -40℃ to +70℃, storage temperature is -50℃ to +80℃.

High and low temperature cycle: After 5 cycles of -40℃ (16 hours) to +70℃ (8 hours), the sheath has no cracks, and the mechanical performance retention rate is ≥80%.

Low-temperature embrittlement: The HDPE sheath has an impact strength of ≥20kJ/m² at -40℃, and a heat distortion temperature of ≥80℃ at high temperatures.

Longitudinal water blocking: No water seepage under 1m water column pressure for 8 hours, and radial water blocking under 100kPa water pressure for 24 hours with no water seepage.

UV resistance: After 1000 hours of xenon lamp aging, the sheath tensile strength retention rate is ≥80%, with no discoloration or cracking.

Chemical corrosion resistance: After soaking in pH4-9 solution for 30 days, the sheath performance has no obvious changes, suitable for industrial polluted areas.

Rodent bite prevention: The steel wire armor can resist rodent gnawing, passing the GB/T 21529-2008 standard test (no obvious damage within 28 days).

Vibration resistance: 10-500Hz sinusoidal vibration (10m/s²) for 2 hours/axis, with no change in fiber attenuation, suitable for rail transit scenarios.

| Core count range | Cable diameter (mm) | Weight (kg/km) | Application scenarios |

|---|

| 2-12 cores | 8-10 | 100-150 | Access networks, user premises networks |

| 24-96 cores | 12-16 | 200-300 | Metropolitan area networks, industrial park interconnections |

| 144-288 cores | 18-22 | 350-500 | Backbone networks, data center interconnections |

Direct burial laying: The double-layer steel wire armor provides mechanical protection, and a burial depth of ≥0.8m can resist the impact of ground activities.

Pipeline laying: The smooth sheath and compact structure support air-blown laying, with a speed of 60-80m/min and a maximum distance of 1000m.

Underwater laying: The full water-blocking design and steel wire armor adapt to environments such as rivers and lakes, with a tensile strength of ≥1500N to resist water flow impact.

Overhead laying: Hanging with hooks, the lightweight design (e.g., 24-core cable weighs 150kg/km) reduces the load on the steel strand.

Railway and highway communication: Vibration resistance and impact resistance ensure stable signal transmission along the line.

Mines and oil fields: The phosphated steel wire reinforcement is corrosion-resistant, supporting the ground communication system in mining areas.

Cross-sea and cross-river communication: The underwater laying with full water-blocking design and steel wire armor has a tensile strength of ≥1500N, ensuring the stability of the cable in ocean currents.

High electromagnetic interference environment: The aluminum tape shielding layer reduces electromagnetic interference, suitable for areas near substations and radar stations.

The production of GYXTA33 strictly follows the following standards:

Domestic standards: GB/T 7424.1-2010 "General Specification for Optical Fibre Cables", YD/T 901-2018 "Stranded Outdoor Optical Cables for Communication".

International standards: IEC 60794-1 "Generic Specification for Optical Fibres and Cables", ITU-T G.652/G.655 optical fiber standards.

Special certifications: UL certification, coal safety certification (for mines), etc. can be provided according to requirements.

| Characteristics | GYXTA33 (central tube type) | GYTA33 (stranded-layer type) |

|---|

| Structure | Central tube + double-layer steel wire armor | Stranded layer + single-layer steel wire armor |

| Diameter | Small (e.g., 12mm for 24-core) | Larger (e.g., 14mm for 24-core) |

| Weight | Light (about 150kg/km) | Heavier (about 180kg/km) |

| Lateral pressure resistance | Higher (2000N/100mm) | Lower (1500N/100mm) |

| Laying methods | Priority for direct burial, underwater, pipeline | Priority for direct burial and overhead |

| Application scenarios | High mechanical protection requirements (e.g., railways) | General direct burial and overhead |

Note:

a.The suffix Xn in the model indicates the selected fiber type, see Yangtze Fiber Model Explanation for details.

b.The color arrangement of the loose tube and fibers can be found in the chromatogram.

c.The minimum thickness of the polyethylene sheath is1.5mm.

d.The cable should not be stored in open-air environments for more than 6 months, otherwise the

spool may be damaged.

e.This document is for reference only and cannot be used as an attachment to the contract. For detailed

product information, please contact our sales staff.