ET optical cables typically enclose 250μm single-mode or multi-mode fibers in loose tubes made of high-modulus materials. This loose tube material has good hydrolysis resistance and high strength, which can provide reliable mechanical protection for the fibers and help reduce the impact of the external environment on the fibers. The loose tube is filled with non-toxic and harmless waterproof compounds, such as special ointments. This not only prevents moisture from entering the fibers but also buffers external pressure to a certain extent, providing key protection for the fibers.

Product Description

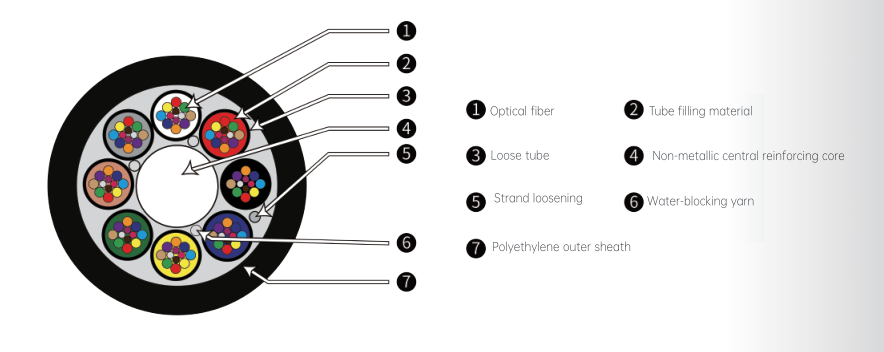

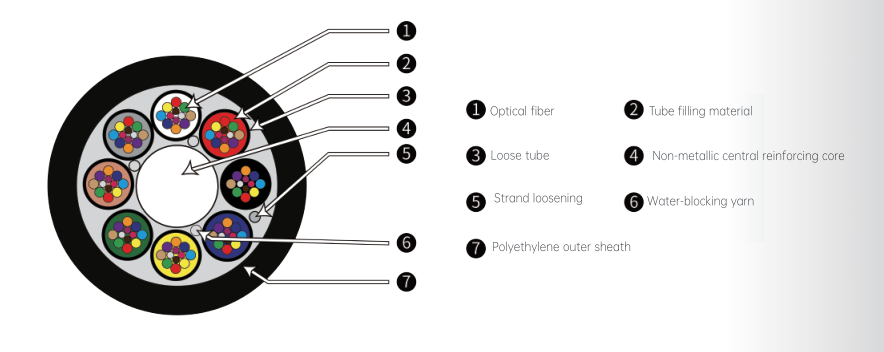

Colored optical fibers are placed in a loose tube made of high-modulus, water-resistant material. The loose tube is filled with a non-toxic, harmless waterproof compound. At the center of the cable core is a non-metallic reinforcing core(FRP), around which the loose tube(or filling yarn)is twisted to form a compact circular cable core. Outside the reinforcing core, there is a water-blocking yarn, followed by extrusion of a black or colored high-density polyethylene sheath to form the cable.

Product Features

◆The use of non-metallic reinforcing elements results in a

small outer diameter, light weight, moderate flexibility, and a

low coefficient of friction for the outer sheath, allowing for

longer air-blowing distances.

◆Special oil paste is filled inside the loose tube to provide

cushioning protection for the optical fibers and to achieve

waterproof performance for the cable.

◆The tight cable structure effectively prevents tube shrinkage.

Fiber Insertion into Loose Tubes: JET optical cables typically enclose 250μm single-mode or multi-mode fibers in loose tubes made of high-modulus materials. This loose tube material has good hydrolysis resistance and high strength, which can provide reliable mechanical protection for the fibers and help reduce the impact of the external environment on the fibers. The loose tube is filled with non-toxic and harmless waterproof compounds, such as special ointments. This not only prevents moisture from entering the fibers but also buffers external pressure to a certain extent, providing key protection for the fibers.

Central Strength Member Design: The center of the cable core is usually a non-metallic strength member (FRP), such as glass fiber reinforced plastic. FRP has high strength, light weight, and good corrosion resistance, which can effectively improve the tensile strength of the optical cable and ensure that the fibers will not break due to tension during laying and use.

Stranded Structure of Loose Tubes: Loose tubes (or filling ropes) are stranded around the central strength member to form a compact circular cable core. This stranded structure can make the structure of the optical cable more stable and help improve the bending performance of the optical cable, so that the optical cable can better protect the fibers when bent and reduce fiber attenuation.

Non-metallic Structure Design: JET optical cable adopts a non-metallic structure, which effectively prevents radio frequency interference and electromagnetic wave interference, making it suitable for occasions with high requirements for electromagnetic compatibility, such as communication equipment rooms and near medical equipment. At the same time, the non-metallic structure also avoids the risk of the optical cable being struck by lightning, improving the safety of use.

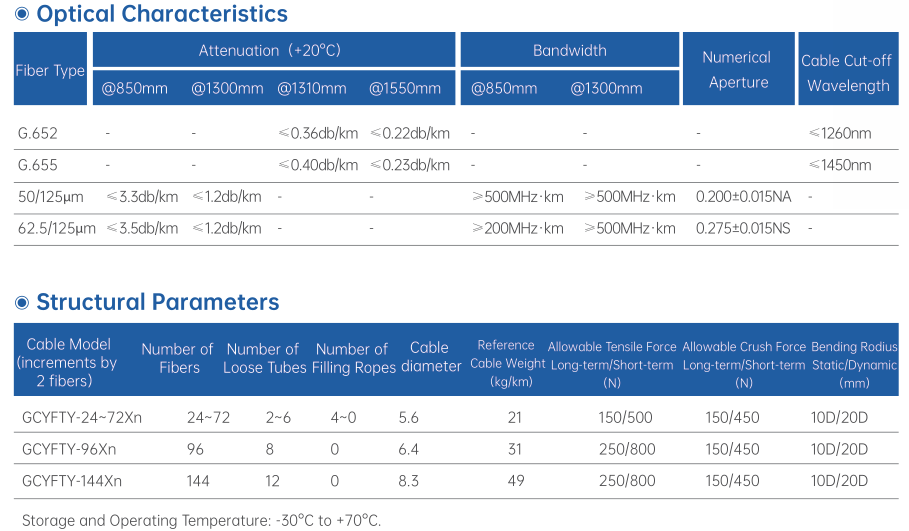

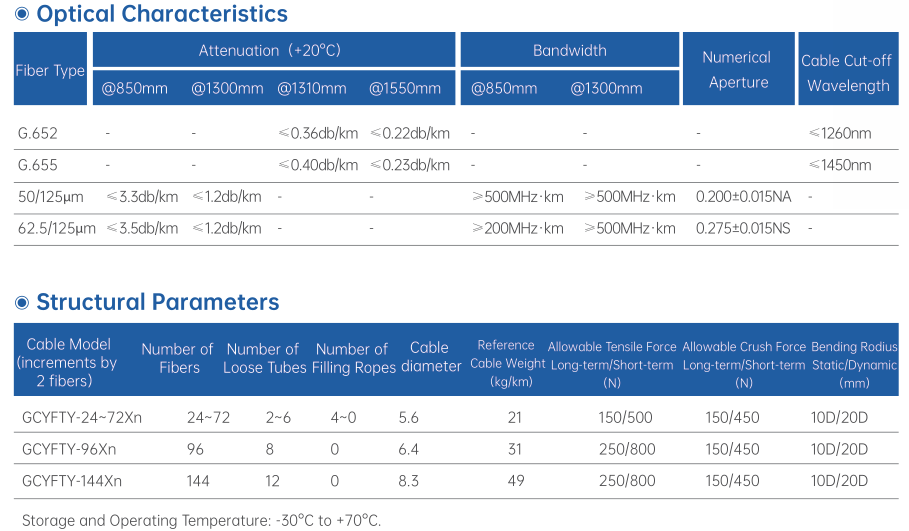

Attenuation Characteristics: The attenuation characteristics of JET optical cable are related to the type of fiber used. For G.652 fiber, at 850nm wavelength, the attenuation is generally ≤3.0dB/km; at 1300nm wavelength, the attenuation is ≤1.0dB/km; at 1310nm wavelength, the attenuation is ≤0.36dB/km; at 1550nm wavelength, the attenuation is ≤0.22dB/km. For G.655 fiber, at 1550nm wavelength, the attenuation is generally ≤0.23dB/km. Lower attenuation means less energy loss when optical signals are transmitted in the optical cable, which can ensure stable signal transmission over longer distances.

Bandwidth Characteristics: The bandwidth of JET optical cable is related to factors such as intermodal dispersion and material dispersion of the fiber. For 50/125μm multimode fiber, at 850nm wavelength, the bandwidth is ≥500MHz·km; at 1300nm wavelength, the bandwidth is ≥1000MHz·km. For 62.5/125μm multimode fiber, at 850nm wavelength, the bandwidth is ≥500MHz·km; at 1300nm wavelength, the bandwidth is ≥600MHz·km. A larger bandwidth allows the optical cable to transmit more information, meeting the needs of high-speed data transmission, such as Internet access and video surveillance services.

Tensile Strength: JET optical cable has excellent tensile performance. Its tensile strength is related to the structural design of the optical cable and the reinforcing elements used. For example, for GYFXTY type JET optical cable, when the number of fibers is 2 - 24 cores, the diameter of the optical cable is 6.0mm, and the allowable long-term tensile force is 1000N, and the short-term tensile force is 2000N; as the diameter of the optical cable increases, the tensile strength also increases accordingly. When the diameter of the optical cable is 7.5mm, the allowable long-term tensile force is 1800N, and the short-term tensile force is 3500N. Good tensile strength ensures that the optical cable will not damage the fibers due to tension during laying and use, whether it is laid by pipeline, overhead or direct burial.

Compressive Strength: JET optical cable needs to have a certain compressive strength to withstand external pressure that may be encountered during laying and use. For example, for GYFXTY type JET optical cable, when the diameter of the optical cable is 6.0mm - 7.5mm, the allowable long-term crushing force is 200 - 250N/100m, and the short-term crushing force is 400 - 500N/100m. Sufficient compressive strength can prevent the fibers from being damaged when the optical cable is subjected to soil pressure, stone extrusion or other external pressures, ensuring the normal operation of the optical cable.

Operating Temperature Range: JET optical cable usually has a wide operating temperature range, generally from -40℃ to +70℃. This enables it to work normally under different climatic conditions, whether in cold northern regions or hot southern regions, it can ensure the stable performance of the optical cable, and will not cause increased fiber attenuation or other performance degradation due to temperature changes.

Waterproof Performance: JET optical cable has good waterproof performance. The structural design such as the waterproof compound filled in the loose tube and the water-blocking yarn outside the cable core can effectively prevent moisture from entering the inside of the optical cable. Generally, it is required that after the optical cable is immersed in water for 24 hours, the additional attenuation of the fiber is not greater than 0.1dB/km, so as to ensure that the optical cable can still work normally in humid environments or underwater environments.

Moisture Resistance: Moisture will age materials such as the sheath and reinforcement of the optical cable, affecting the service life of the optical cable. The moisture resistance of JET optical cable is usually measured by the water absorption rate of the sheath, which is generally required to be no more than 0.5%, which helps to ensure that the performance of the optical cable will not be significantly affected by moisture erosion during long-term use.

In summary, JET optical cable has excellent performance in structural design, optical characteristics, mechanical properties, and environmental adaptability. Its unique structural design, excellent optical and mechanical properties, and good environmental performance make it an important choice in the field of optical fiber communication, and can meet the needs of various complex communication environments and application scenarios. With the continuous development of communication technology, JET optical cable will play a more important role in the construction of communication networks.

Note:

a.The suffix Xn in the model indicates the selected fiber

type, see Yangtze Fiber Model Explanation for details.

b.The color arrangement of the loose tube and fibers can

be found in the chromatogram.

c.The minimum thickness of the polyethylene sheath is

1.5mm.

d.The cable should not be stored in open-air environ-

ments for more than 6 months, otherwise the spool

may be damaged.

e.This document is for reference only and cannot be

used as an attachment to the contract. For detailed

product information, please contact our sales staff.