GJFDV optical cable, with its butterfly flat structure, non-metallic strength member, and low bending loss fiber as the core, demonstrates comprehensive advantages of lightweight, easy installation, and high reliability in indoor cabling scenarios. Its parameter design accurately matches the needs of FTTH access, smart homes, data centers, and other scenarios. Through strict material selection and structural optimization, it balances performance, cost, and construction convenience.

With the popularization of 5G gigabit broadband and full-house optical networks, GJFDV optical cable will be upgraded towards higher bandwidth (supporting 50G/100G transmission), low-smoke halogen-free sheath (more environmentally friendly), and rodent-proof design (adapting to low-rise residences), continuously providing better solutions for indoor fiber optic cabling.

Product Description

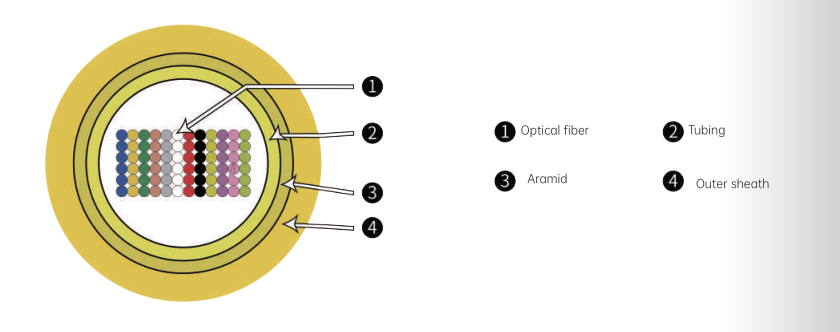

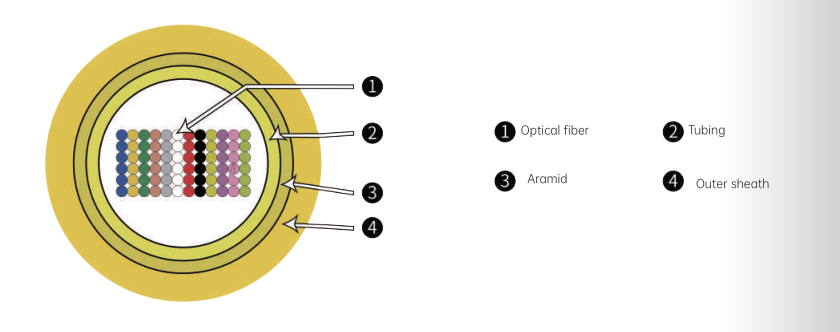

The indoor ribbon fiber optic cable utilizes ribbon fiber as the optical transmission medium, which is enclosed in a loose tube made of high modulus material, and then wrapped with a layer of aramid strength member. Finally, it is extruded with a layer of polyethylene sheath.

Product Feature

Using ribbon fiber achieves high integration. Aramid yarn strength members provide outstanding tensile performance for the cable.

◆The outer sheath material offers corrosion resistance, waterproofing, flameresistance,and environmental friendliness.

Product Applications

• Indoor wiring

•Interconnection of instruments and communication equipment.

GJFDV optical cable adopts a flat butterfly structure with a rectangular or approximately rectangular cross-section, usually 3.0-6.0mm in width and 2.0-3.5mm in thickness. A single cable weighs ≤100g/m, which is more than 30% lighter than traditional circular indoor optical cables. The core advantages of this design are: first, it reduces the space occupied by cabling, suitable for narrow environments such as in-wall pipe threading and trunking installation; second, the flat structure has better anti-torsion performance, avoiding fiber micro-bending loss caused by torsion during installation; third, it facilitates quick sheath stripping, improving splicing efficiency by more than 40%.

The cable has two parallel strength members symmetrically distributed along its length, with a fiber protection unit in the middle and sheath reinforcing edges on both sides. The overall structure is formed in one piece through an extrusion molding process, with a dimensional deviation controlled within ±0.2mm to ensure structural stability.

The strength member of GJFDV optical cable is made of Glass Fiber Reinforced Plastic (FRP) with a diameter of 0.5-1.0mm. A single FRP has a tensile strength of ≥800MPa and an elastic modulus of ≥100GPa. Compared with metal strength members (such as steel wires), FRP has three major advantages:

Excellent insulation: Volume resistivity ≥10¹⁴Ω·cm, avoiding electromagnetic interference in strong electrical environments (such as 220V power lines) and ensuring stable optical signal transmission.

Lightweight: FRP has a density of only 2.0-2.2g/cm³, 70% lighter than steel wire (7.8g/cm³), reducing the load on walls and trunking during cabling.

Corrosion resistance: No rust risk in humid environments. After 1000 hours of salt spray test (5% NaCl solution, 35℃), the mechanical property retention rate is ≥90%.

The FRP strength member is tightly bonded to the sheath through an interface bonding process, with a peel strength of ≥1.5N/cm, preventing separation between the strength member and the sheath during installation, which could lead to structural failure.

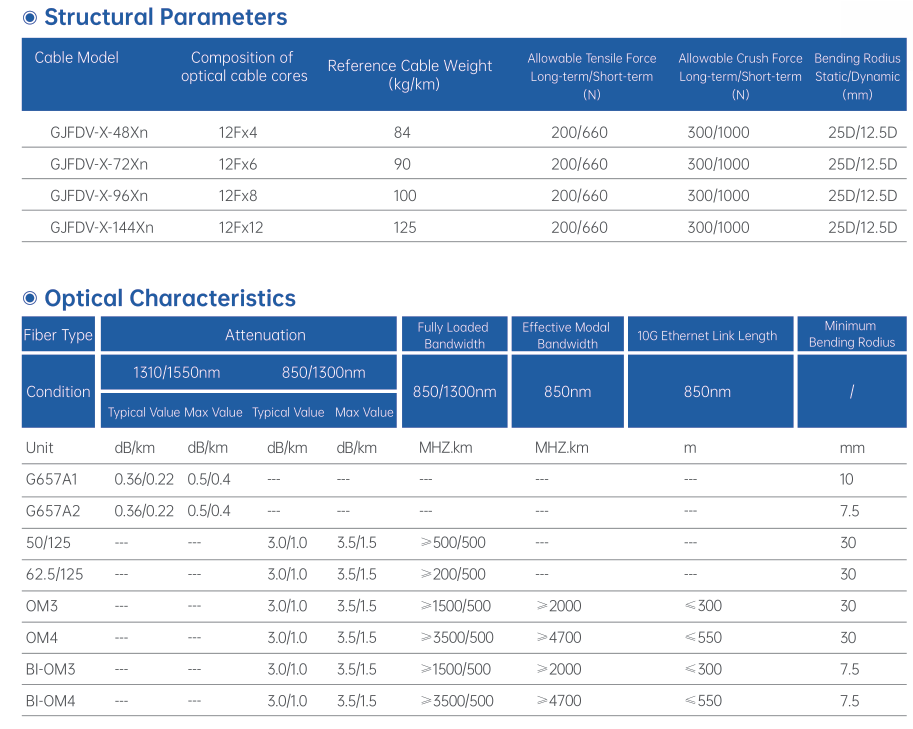

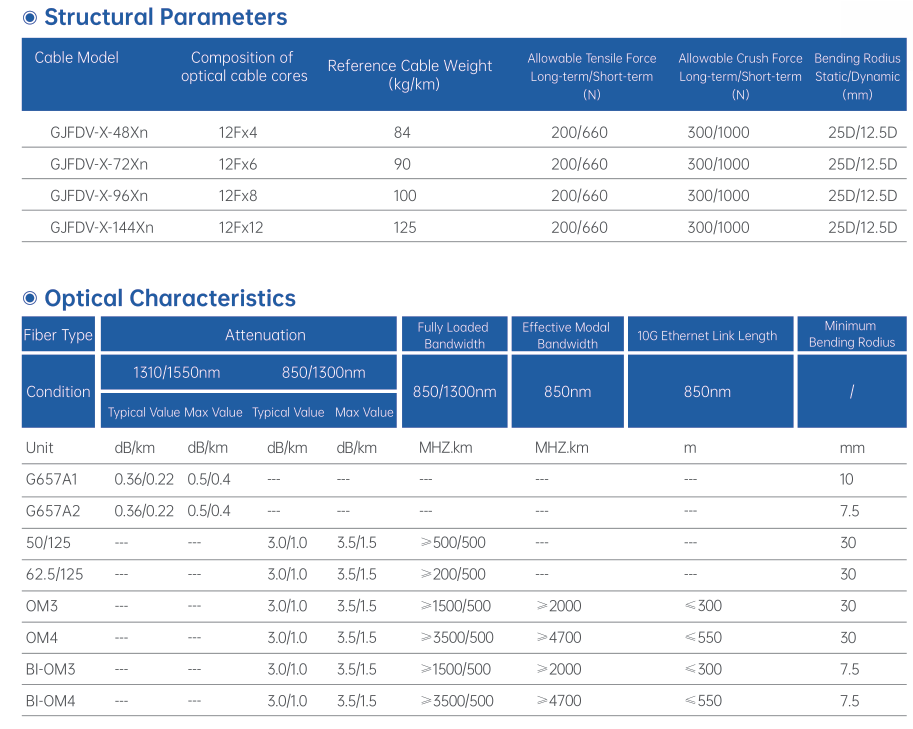

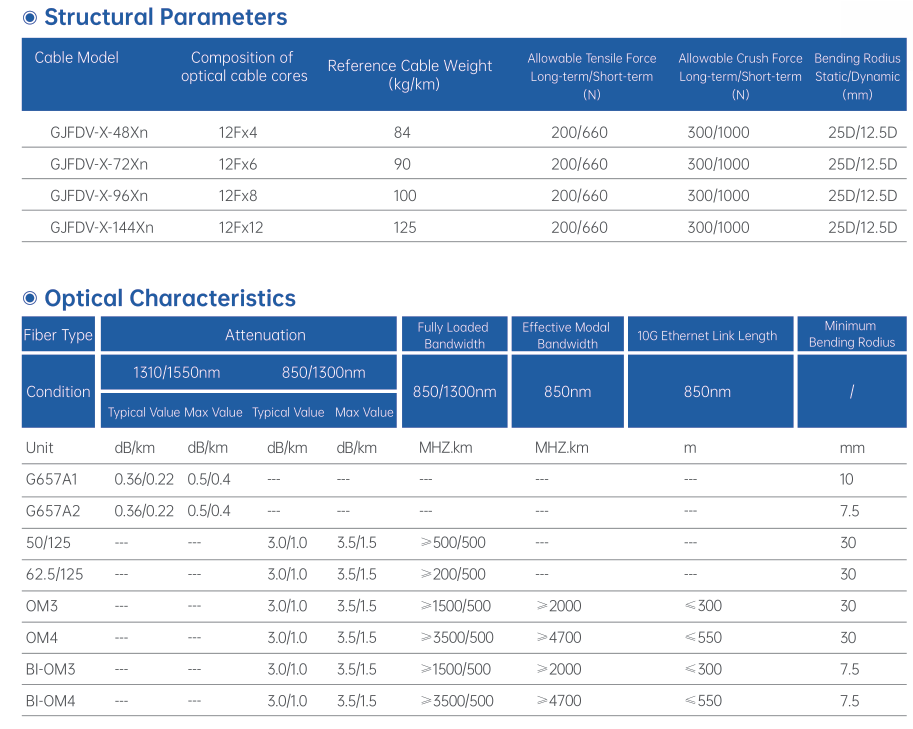

The core transmission medium of GJFDV optical cable is G.657A1 or G.657A2 single-mode fiber, and some specifications can use OM3/OM4 multi-mode fiber. The specific parameters are as follows:

G.657A1 fiber: Suitable for scenarios with strict bending radius requirements. At a 10mm bending radius (1550nm wavelength), the additional loss is ≤0.1dB. The attenuation at 1310nm wavelength is ≤0.36dB/km, and at 1550nm is ≤0.22dB/km.

G.657A2 fiber: Balances bending performance and transmission distance. At a 7.5mm bending radius, the additional loss is ≤0.2dB, supporting 10Gbps signal transmission over a distance of up to 300m.

OM3 multi-mode fiber: Attenuation at 850nm wavelength is ≤3.5dB/km, bandwidth ≥2000MHz·km, supporting 10 Gigabit Ethernet transmission.

The fiber coating adopts a double-layer structure (inner UV-cured resin + outer buffer layer) with a diameter of 250μm. The stripping force is controlled between 0.5-3.0N, facilitating quick stripping during splicing without damaging the fiber.

The fiber is wrapped in a Polybutylene Terephthalate (PBT) loose tube with an inner diameter of 1.5-2.0mm. The tube is filled with semi-fluid waterproof gel (dropping point ≥60℃), which remains fluid within the range of -20℃ to +60℃. It can buffer mechanical shocks and prevent moisture intrusion. The loose tube is arranged parallel to the FRP strength members on both sides, with a spacing error of ≤0.3mm, ensuring uniform force on the fiber during stress and reducing micro-bending loss.

The sheath of GJFDV optical cable is made of Polyvinyl Chloride (PVC), complying with GB/T 8815-2008 "Soft Polyvinyl Chloride Plastics for Wires and Cables" standard, with the following specific characteristics:

Mechanical properties: Tensile strength ≥12MPa, elongation at break ≥150%, hardness (Shore A) 80-90 at room temperature, combining flexibility and structural strength.

Flame retardancy: Passes UL94 V-0 grade test (self-extinguishing within 10 seconds in vertical burning test, no dripping to ignite cotton below), oxygen index ≥28%, meeting indoor fire safety requirements.

Environmental resistance: Acid and alkali resistance (soaked in 5% H₂SO₄ or 5% NaOH solution for 72 hours, weight change rate ≤1%, tensile strength retention rate ≥80%), suitable for mild corrosive environments such as kitchens and laboratories.

The sheath surface is printed with identification information (model, core count, meter marking, etc.) using scratch-resistant ink, which remains clearly visible after 100 friction tests (load 500g), facilitating construction traceability.

Attenuation is a core indicator measuring cable transmission efficiency. The attenuation performance of GJFDV optical cable is achieved through strict control of fiber quality and structural design:

In the temperature cycle test (-20℃ to +60℃, 10 cycles), the additional fiber attenuation is ≤0.1dB/km, demonstrating excellent transmission stability under indoor temperature fluctuations.

One of the core advantages of GJFDV optical cable is low bending loss, which stems from the synergy between the design of G.657 fiber and the butterfly structure:

Static bending: Bending 100 turns with a 10mm radius (for G.657A1 fiber), the additional loss at 1550nm wavelength is ≤0.1dB; bending 100 turns with a 7.5mm radius (for G.657A2 fiber), the additional loss is ≤0.2dB.

Dynamic bending: Reciprocating bending 1000 times with a 20mm radius (bending angle ±90°), the additional loss is ≤0.3dB, meeting the needs of scenarios requiring frequent movement or cabling adjustments.

Macro-bending and micro-bending: Passing IEC 60793-1-47 standard test, macro-bending loss (30mm radius, 10 turns) ≤0.1dB; micro-bending loss (after temperature cycle + vibration test) ≤0.1dB/km, ensuring no performance degradation during long-term use.

The dispersion performance of G.657A1/A2 fiber is suitable for high-speed signal transmission:

Zero dispersion wavelength: 1300-1324nm, zero dispersion slope ≤0.092ps/(nm²·km);

1550nm wavelength dispersion: ≤18ps/(nm·km), supporting 10Gbps signal transmission over a distance of ≥40km, and 25Gbps signal over ≥10km.

OM3/OM4 multi-mode fiber achieves high bandwidth through optimized refractive index distribution:

OM3 fiber: 850nm wavelength effective modal bandwidth (EMB) ≥2000MHz·km, 1300nm ≥500MHz·km;

OM4 fiber: 850nm EMB ≥4700MHz·km, supporting 100Gbps Ethernet transmission over a distance of 150m.

The tensile performance of GJFDV optical cable is designed for indoor installation needs, with two working conditions: short-term (during installation) and long-term (during use):

Short-term tensile strength: ≥600N (application speed 10mm/min, maintaining 600N for 1 minute, additional fiber attenuation ≤0.1dB), meeting the instantaneous tension requirements during traction installation.

Long-term tensile strength: ≥300N (continuously applying 300N tension for 24 hours, no fiber breakage, additional attenuation ≤0.1dB), adapting to slight tension that may occur after cabling (such as tension caused by wall settlement).

The tensile performance is guaranteed by the synergy between the FRP strength member and the sheath: FRP bears the main tension, and the sheath disperses the stress to the overall structure through bonding technology, preventing the fiber from being stressed.

In indoor environments, optical cables may withstand lateral pressure from furniture compression and trampling. The compressive performance parameters of GJFDV are as follows:

Short-term lateral pressure: ≥1000N/100mm (pressure application speed 10mm/min, maintaining for 1 minute), no sheath rupture, additional fiber attenuation ≤0.1dB.

Long-term lateral pressure: ≥500N/100mm (continuously applying 500N pressure for 24 hours), no permanent structural deformation, stable fiber performance.

The core of the compressive design is the force dispersion of the flat structure: the butterfly cross-section evenly distributes the pressure to the strength members and sheath edges on both sides, and the pressure on the fiber unit in the middle is ≤5N, much lower than the fiber compressive limit (≥100N).

Through a 1.5m free fall test (cable ends fixed, middle suspended, falling from 1.5m height to concrete ground), the sheath has no cracks, and the additional fiber attenuation is ≤0.1dB. Impact energy is absorbed by the elastic deformation of the PVC sheath, and the FRP strength member limits excessive deformation to protect the fiber from impact damage.

In a 10-500Hz sinusoidal vibration test (acceleration 10m/s², vibrating for 2 hours per axis), there is no significant change in fiber attenuation (change ≤0.1dB/km), and no loosening at the joints, suitable for scenarios with vibration sources (such as near room air conditioners).

The flexibility of GJFDV optical cable adapts to complex indoor cabling needs:

Static bending radius: ≤10mm (for G.657A1 fiber), which can be installed around wall corners and furniture edges without excessive space reservation.

Dynamic bending radius: ≤20mm (during installation), allowing quick adjustment of direction during construction, reducing cabling difficulty.

Minimum bending diameter: A single cable can be wound on a cylinder with a diameter of 10mm (such as a spool) without permanent deformation, facilitating storage and transportation.

Indoor temperature fluctuations are relatively mild, but GJFDV still has wide temperature adaptability:

Operating temperature range: -20℃ to +60℃, covering indoor heating environments in northern winter (≥18℃), unairconditioned environments in southern summer (≤40℃), and constant temperature environments in equipment rooms (20-25℃).

Storage temperature range: -40℃ to +70℃, withstanding extreme temperatures during transportation and storage without sheath cracking or fiber embrittlement risks.

Temperature cycle test: After 10 cycles of -20℃ (8 hours) → room temperature (2 hours) → +60℃ (8 hours) → room temperature (2 hours), the fiber attenuation change is ≤0.05dB/km, and the sheath thermal shrinkage rate is ≤1%.

The flame retardancy of indoor optical cables is directly related to fire safety. The core indicators of GJFDV are as follows:

Flame retardant grade: UL94 V-0 (vertical burning), GB/T 18380.1-2008 Class B (bundle burning), flame spread length ≤0.5m, no dripping to ignite combustibles below.

Smoke density: In GB/T 17651.2-1998 test, maximum smoke density (MSD) ≤75, smoke density rating (SDR) ≤50, reducing the impact of smoke on personnel evacuation during fires.

Halogen acid gas release: Although the PVC sheath contains halogens, through formula optimization, the halogen acid gas release amount is ≤5mg/g, meeting GB/T 17650.1-1998 standard, reducing the harm of corrosive gases during fires.

Indoor environments may have moisture (such as near bathrooms) or mildew growth risks. The protection performance of GJFDV is as follows:

Moisture resistance: Placed in a 40℃, 95% relative humidity environment for 1000 hours, the sheath water absorption rate is ≤0.5%, fiber attenuation change is ≤0.1dB/km, and no mildew spots are formed.

Mildew resistance: Passing GB/T 2423.16-2013 mildew test (inoculated with 5 types of mildew such as Aspergillus niger and Aspergillus flavus), mildew growth grade ≤1 (almost no growth) after 28 days, avoiding sheath aging caused by mildew erosion.

After contact with common indoor chemicals (such as detergent, alcohol, household cleaners), the sheath has no swelling or cracking. After 24-hour immersion, the tensile strength retention rate is ≥90%, suitable for kitchens, laboratories, and other scenarios.

Through a wear test (rubbing the sheath surface with sandpaper under 5N pressure for 100 times), the wear depth is ≤0.1mm, with no fiber exposure risk, extending service life. The hardness and elasticity balance of the PVC sheath combines wear resistance and flexibility.

GJFDV optical cable provides various core counts and length specifications to meet different scenario needs:

| Core count | Cable size (width × thickness) | Weight (g/m) | Maximum transmission distance (10Gbps) | Application scenarios |

|---|

| 1 core | 3.0mm×2.0mm | 20-30 | 300m (G.657A2) | Home FTTH access |

| 2 cores | 4.0mm×2.5mm | 30-40 | 300m | Enterprise desktop cabling, IPTV + broadband |

| 4 cores | 5.0mm×3.0mm | 40-50 | 300m | Small equipment rooms, multimedia classrooms |

Length specifications include 100m/roll, 500m/reel, and 1000m/reel, which can be cut according to construction needs. The meter marking error is ≤0.5%, facilitating accurate measurement.

As the drop cable from the corridor fiber distribution box to the user's home, GJFDV has significant advantages:

The flat structure can be inserted into wall ducts (inner diameter ≥5mm) without drilling large holes.

Non-metallic strength members avoid electromagnetic interference when laid in the same pipe as strong electric lines (such as 220V power lines).

Low bending loss allows installation around door frames and baseboards, which is aesthetically pleasing and does not affect daily life.

In office buildings, hotels, and other scenarios, it is used to connect floor distribution frames and desktop information points:

Multi-core specifications (2-4 cores) support integrated transmission of voice, data, and video services.

Flame retardancy reduces fire risks, complying with building fire codes.

Lightweight design reduces trunking load, facilitating installation with network cables and power lines in the same trunking.

Used for internal equipment interconnection or short-distance jumpers in cabinets:

Small bending radius adapts to dense cabling in cabinets, saving space.

High bandwidth supports 10Gbps/25Gbps signal transmission, meeting server and switch interconnection needs.

Vibration resistance ensures stable signals during equipment operation in the room.

Connecting smart terminals (such as high-definition cameras, smart door locks) and home gateways:

Mildew resistance adapts to humid environments such as bathrooms and kitchens.

Wear-resistant sheath withstands daily touch and cleaning, extending service life.

Low loss ensures smooth transmission of high-definition video (4K/8K).

The structural design of GJFDV fully considers construction convenience:

Easily strippable sheath: The sheath can be stripped off at one time with a special wire stripper, exposing the fiber and strength member. The stripping length error is ≤1mm, improving splicing efficiency by 30%.

Compatible with quick connectors: After fiber end face treatment, it can be directly adapted to SC/LC quick connectors, with an average splicing time of ≤3 minutes/core. No hot-melt equipment is needed, suitable for home access construction.

Clear identification: Meter markings are spaced 1m apart, facilitating calculation of installation length and avoiding waste; core color differentiation (blue, orange) facilitates polarity identification.

The production of GJFDV optical cable strictly follows domestic and foreign standards:

Domestic standards: GB/T 18280.1-2015 "Indoor Optical Cables Part 1: General Principles", YD/T 1997-2009 "Butterfly Drop Cables for Access Networks".

International standards: IEC 60794-1-2 "Fiber Optic Cables Part 1-2: General Principles—Indoor Cables", TIA-568.3-D "Fiber Optic Cabling Components Standard".

Each batch of cables must pass more than 20 tests before leaving the factory, with core items including:

Optical performance: Attenuation, dispersion, bending loss (10mm radius).

Mechanical performance: Tensile, compressive, impact, vibration, bending fatigue.

Environmental performance: Flame retardancy, temperature resistance, moisture resistance, mildew test.

Structural performance: Sheath thickness, strength member diameter, fiber excess length.

| Characteristics | GJFDV (butterfly non-metallic) | GJFJV (butterfly metal reinforced) | GJPFJV (circular indoor cable) |

|---|

| Strength member material | FRP (non-metallic) | Steel wire (metal) | FRP/steel wire |

| Bending radius | ≤10mm | ≤15mm | ≤20mm |

| Flame retardant grade | UL94 V-0 | UL94 V-0 | UL94 V-2 |

| Anti-electromagnetic interference | Excellent (non-metallic) | Poor (metal easily induces interference) | Depends on strength member type |

| Weight (2 cores) | 30g/m | 45g/m | 50g/m |

| Application scenarios | Home access, indoor cabling | High-strength scenarios (such as overhead) |

|

![]()